| Citation: | Yi-Xin Zhang, Zhen-Hua Ge. The stability of copper sulfides thermoelectric materials[J]. Materials Lab, 2024, 3(1): 230017. doi: 10.54227/mlab.20230017 |

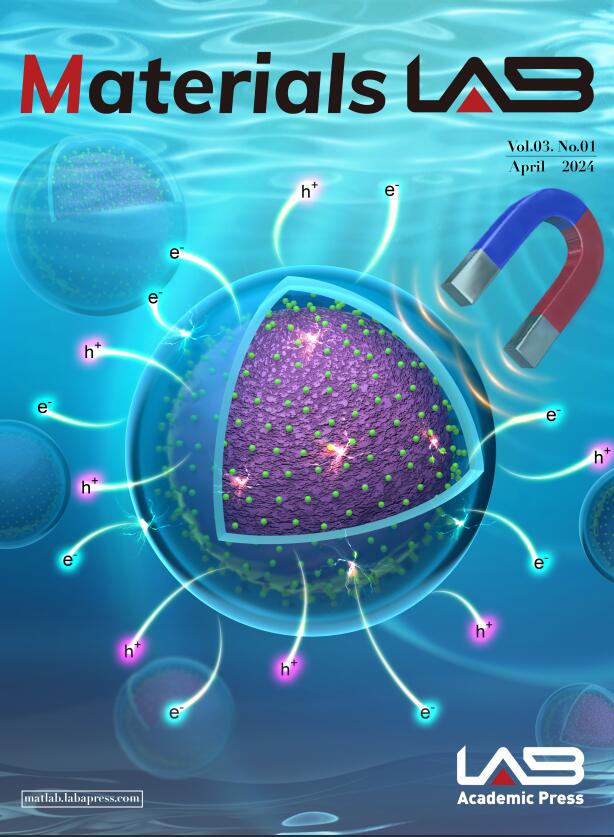

The stability of copper sulfides thermoelectric materials

-

Abstract

The stability of thermoelectric materials is critical in determining their suitability for commercial device applications. Copper sulfides are superionic conductors with highly disordered Cu ions, which results in exceptional thermoelectric properties at high temperature. However, this feature also causes unbalanced Cu ions concentration as well as the poor service stability under external fields. Researchers are focusing on enhancing the service stability of copper-based superionic conductors. This perspective reviews the mechanisms of Cu ions migration, metal deposition, and materials degradation of copper sulfides. The importance of appropriately inhibiting long-range migration of Cu ions is emphasized. Based on an analysis of the effects of multiple scaled ion-blocking barriers on ion, carrier and phonon transportation, some rational approaches for improving service stability of copper sulfides while maintaining their thermoelectric performance are proposed, which would increase the possibility of utilizing copper sulfides in thermoelectric device applications.

-

-

References

1. J. Li, Y. Pan, C. Wu, F. Sun and T. Wei, Sci. China Technol. Sci., 2017, 60, 1347 2. Y. Xiao and L.-D. Zhao, Science, 2020, 367, 1196 3. B. Qin and L.-D. Zhao, Mat. Lab, 2022, 1, 220004 4. T.-R. Wei, M. Jin, Y. Wang, H. Chen, Z. Gao, K. Zhao, P. Qiu, Z. Shan, J. Jiang, R. Li, L. Chen, J. He and X. Shi, Science, 2020, 369, 542 5. Y. Xiao, Mat. Lab, 2022, 1, 220025 6. X. Zhang and L.-D. Zhao, J. Materiomics, 2015, 1, 92 7. L. Su, D. Wang, S. Wang, B. Qin, Y. Wang, Y. Qin, Y. Jin, C. Chang and L.-D. Zhao, Science, 2022, 375, 1385 8. W. He, D. Wang, H. Wu, Y. Xiao, Y. Zhang, D. He, Y. Feng, Y.-J. Hao, J.-F. Dong, R. Chetty, L. Hao, D. Chen, J. Qin, Q. Yang, X. Li, J.-M. Song, Y. Zhu, W. Xu, C. Niu, X. Li, G. Wang, C. Liu, M. Ohta, S. J. Pennycook, J. He, J.-F. Li and L.-D. Zhao, Science, 2019, 365, 1418 9. P. Qiu, T. Mao, Z. Huang, X. Xia, J. Liao, M. T. Agne, M. Gu, Q. Zhang, D. Ren, S. Bai, X. Shi, G. J. Snyder and L. Chen, Joule, 2019, 3, 1 10. D. R. Brown, T. Day, T. Caillat and G. J. Snyder, J. Electron. Mater., 2013, 42, 2014 11. Y. He, T. Day, T. Zhang, H. Liu, X. Shi, L. Chen and G. J. Snyder, Adv. Mater., 2014, 26, 3974 12. Y. Liu, M. Liu, M. T. Swihart, J. Am. Chem. Soc., 2017, 139, 18598 13. Y. Shang, X. Li, S. Huang, S. Chen, Z. Yang, L. Guo, H. Y. Yang, Matter, 2020, 2, 1 14. Z.-H. Ge, B.-P. Zhang, Y.-X. Chen, Z.-X. Yu, Y. Liu and J.-F. Li, Chem. Commun., 2011, 47, 12697 15. J. Cui, R. Jiang, W. Lu, S. Xu, L. Wang, Small, 2017, 13, 1602235 16. P. Lukashev, W. R. L. Lambrecht, T. Kotani and M. V. Schilfgaarde, Phys. Rev. B, 2007, 76, 195202 17. Q. Xu, B. Huang, Y.-F. Zhao, Y.-f. Yan and R. Noufi, Appl. Phys. Lett., 2012, 100, 061906 18. H. Liu, X. Shi, F. Xu, L. Zhang, W. Zhang, L. Chen, Q. Li, C. Uher, T. Day and G. J. Snyder, Nat. Mater., 2012, 11, 422 19. Y.-X. Sun, L.-l. Xi, J. Yang, L.-H. Wu, X. Shi, L.-D. Chen, J. Snyder, J.-H. Yang and W.-Q. Zhang, J. Mater. Chem. A, 2017, 5, 5098 20. L. Zhao, X. Wang, F. Y. Fei, J. Wang, Z. Cheng, S. Dou, J. Wang and G. J. Snyderc, J. Mater. Chem. A, 2015, 3, 9432 21. Q.-L. Meng, S. Kong, Z. Huang, Y. Zhu, H.-C. Liu, X. Lu, P. Jiang and X. Bao, J. Mater. Chem. A, 2016, 4, 12624 22. Z.-H. Ge, X. Liu, D. Feng, J. Lin and J. He, Adv. Energy Mater., 2016, 6, 1600607 23. D.-D. Liang, Z.-H. Ge, H.-Z. Li, B.-P. Zhang and F. Li, J. Alloys Compd., 2017, 708, 169 24. K. Zhao, C. Zhu, P. Qiu, A. B. Blichfeld, E. Eikeland, D. Ren, B. B. Iversen, F. Xu, X. Shi and L. Chen, Nano Energy, 2017, 42, 43 25. H. Tang, F.-H. Sun, J.-F. Dong, Asfandiyar, H.-L. Zhuang, Y. Pan and J.-F. Li, Nano Energy, 2018, 49, 267 26. Z.-H. Ge, Y.-X. Zhang, D. Song, X. Chong, P. Qin, F. Zheng, J. Feng and L.-D. Zhao, J. Mater. Chem. A, 2018, 6, 14440 27. Y. Yao, B.-P. Zhang, J. Pei, Q. Sun, G. Nie, W.-Z. Zhang, Z.-T. Zhuo and W. Zhou, ACS Appl. Mater. Inter., 2018, 10, 32201 28. P. Qin, Z.-H. Ge, Y.-X. Chen, X. Chong, J. Feng and J. He, Nanotechnology, 2018, 29, 345402 29. X. Liang, D. Jin and F. Dai, Adv. Electron. Mater., 2019, 5, 1900486 30. Z.-H. Ge, X. Chong, D. Feng, Y.-X. Zhang, Y. Qiu, L. Xie, P.-W. Guan, J. Feng and J. He, Mater. Today Phys., 2019, 8, 71 31. A. Mikuła, P. Nieroda, K. Mars, J. Dąbrowa and A. Koleżyński, Solid State Ionics, 2020, 350, 115322 32. C. Tang, D. Liang, H. Li, K. Luo and B. Zhang, J. Adv. Ceram., 2019, 8, 209 33. T. Mao, P. Qiu, J. Liu, X. Du, P. Hu, K. Zhao, D. Ren, X. Shi and L. Chen, Phys. Chem. Chem. Phys., 2020, 22, 7374 34. X. Chen, H. Zhang, Y. Zhao, W.-D. Liu, W. Dai, T. Wu, X. Lu, C. Wu, W. Luo, Y. Fan, L. Wang, W. Jiang, Z.-G. Chen and J. Yang, ACS Appl. Mater. Inter., 2019, 11, 22457 35. P. Nieroda, J. Leszczyński, A. Mikuła, K. Mars, M. J. Kruszewskic and A. Koleżyński, Ceram. Int., 2020, 46, 25460 36. F. Shen, Y. Zheng, L. Miao, C. Liu, J. Gao, X. Wang, P. Liu, K. Yoshida and H. Cai, ACS Appl. Mater. Inter., 2020, 12, 8385 37. T. Mao, P. Qiu, P. Hu, X. Du, K. Zhao, T.-R. Wei, J. Xiao, X. Shi and L. Chen, Adv. Sci., 2020, 7, 1901598 38. S. Zhao, H. Chen, X. Zhao, J. Luo, Z. Tang, G. Zeng, K. Yang, Z. Wei, W. Wen, X. Chen and Y. Sun, Mater. Today Phys., 2020, 15, 100271 39. R. Zhang, J. Pei, Z.-J. Han, Y. Wu, Z. Zhao and B.-P. Zhang, J. Adv. Ceram., 2020, 9, 535 40. Y.-H. Zhao, R. Zhang, B.-P. Zhang, Y. Yin, M.-J. Wang and D.-D. Liang, Acta Phys. Sin., 2021, 70, 128401 41. M. Li, Y. Liu, Y. Zhang, X. Han, T. Zhang, Y. Zuo, C. Xie, K. Xiao, J. Arbiol, J. Llorca, M. Ibáñez, J. Liu and A. Cabot, ACS Nano, 2021, 15, 4967 42. Y.-X. Zhang, Y.-K. Zhu, J. Feng and Z.-H. Ge, J. Alloys Compd., 2022, 892, 162035 43. Z. Yue, W. Zhou, X. Ji, Y. Wang and F. Guo, Chem. Eng. J, 2022, 449, 137748 44. M. Yang, X. Liu, B. Zhang, Y. Chen, H. Wang, J. Yu, G. Wang, J. Xu, X. Zhou and G. Han, ACS Appl. Mater. Inter., 2021, 13, 39541 45. Y. Zhang, C. Xing, Y. Liu, M. C. Spadaro, X. Wang, M. Li, K. Xiao, T. Zhang, P. Guardia, K. H. Lim, A. O. Moghaddam, J. Llorca, J. Arbiol, M. Ibanez and A. Cabot, Nano Energy, 2021, 85, 105991 46. S. Xiang, Y. Liang, X. Han, P. Yan and X. Zhang, Inorg. Chem., 2022, 61, 14973 47. Y.-X. Zhang, T.-Y. Yang, Z.-Y. Wang, J. Feng and Z.-H. Ge, Mater. Today Phys., 2022, 27, 100808 48. Y.-X. Zhang, J. Feng and Z.-H. Ge, Chem. Eng. J., 2022, 428, 131153 49. Y.-X. Zhang, Q. Lou, Z.-H. Ge, S.-W. Gu, J.-X. Yang, J. Guo, Y.-K. Zhu, Y. Zhou, X.-H. Yu, J. Feng and J. He, Acta Mater., 2022, 233, 117972 50. Y. Yu, D. Yang, J. Li, M. Zhang, H. Luo, Q. Liang, Hengqiang Ye, Q. Zhang, X. Tang and J. Wu, Adv. Func. Mater., 2022, 32, 2107284 51. X. Li, Y. Lou, K. Jin, L. Fu, P. Xu, Z. Shi, T. Feng and B. Xu, Angew. Chem. Int. Ed., 2022, 61, e202212885 52. S. Xiang, Y. Liang and X. Zhang, J. Eur. Ceram. Soc., 2022, 42, 7468 53. W. Zhou, H. Li, Z. Shan, R. Zhang, S. Lu, J. Pei, Z. Ge, M. Zhou, Y. Wang and B. Zhang, Sci. China Mater., 2023, 66, 2051 54. P. Qiu, M. T. Agne, Y. Liu, Y. Zhu, H. Chen, T. Mao, J. Yang, W. Zhang, S. M. Haile, W. G. Zeier, J. Janek, C. Uher, X. Shi, L. Chen and G. J. Snyder, Nat. Commun., 2018, 9, 2910 55. S.-Y. Miyatani, Y. Suzuki, J. Phys. Soc. Jpn., 1953, 8, 680 56. G. Dennler, R. Chmielowski, S. Jacob, F. Capet, P. Roussel, S. Zastrow, K. Nielsch, I. Opahle and G. K. H. Madsen, Adv. Energy Mater., 2014, 4, 1301581 57. P. Qin, X. Qian, Z.-H. Ge, L. Zheng, J. Feng and L.-D. Zhao, Inorg. Chem. Front., 2017, 4, 1192 58. W.-D. Liu, X.-L. Shi, H. Gao, R. Moshwan, S.-D. Xu, Y. Wang, L. Yang, Z.-G. Chen and J. Zou, J. Mater. Chem. C, 2019, 7, 5366 59. Y. He, P. Lu, X. Shi, F. Xu, T. Zhang, G. J. Snyder, C. Uher and L. Chen, Adv. Mater., 2015, 27, 3639 60. P. Nieroda, M. J. Kruszewski, J. Leszczynski, K. Mars and A. Kolezynski, Ceram. Int., 2023, 49, 9681 61. A. A. Olvera, N. A. Moroz, P. Sahoo, P. Ren, T. P. Bailey, A. A. Page, C. Uher and P. F. P. Poudeu, Energ. Environ. Sci., 2017, 10, 1668 62. S. Wu, J. JIANG, Y. Liang, P. Yang, Y. Niu, Y. Chen, J. Xia and C. Wang, J. Electron. Mater., 2017, 46, 2432 63. Y. Dou, Z. Liu, Z. Wu, Y. Liu, J. Li, C. Leng, D. Fang, G. Liang, J. Xiao, W. Li, X. Wei, F. Huang, Y.-B. Cheng and J. Zhong, Nano Energy, 2020, 71, 104567 64. Z. Zhao, D.-D. Liang, J. Pei, J.-L. Shi, Y. Wu, R. Zhang and B.-P. Zhang, J. Materiomics, 2021, 7, 556 -

Rights and permissions

This is an open access article under the terms of the Creative Commons Attribution License, which permits use, distribution and reproduction in any medium, provided the original work is properly cited.

Information

Article Metrics

-

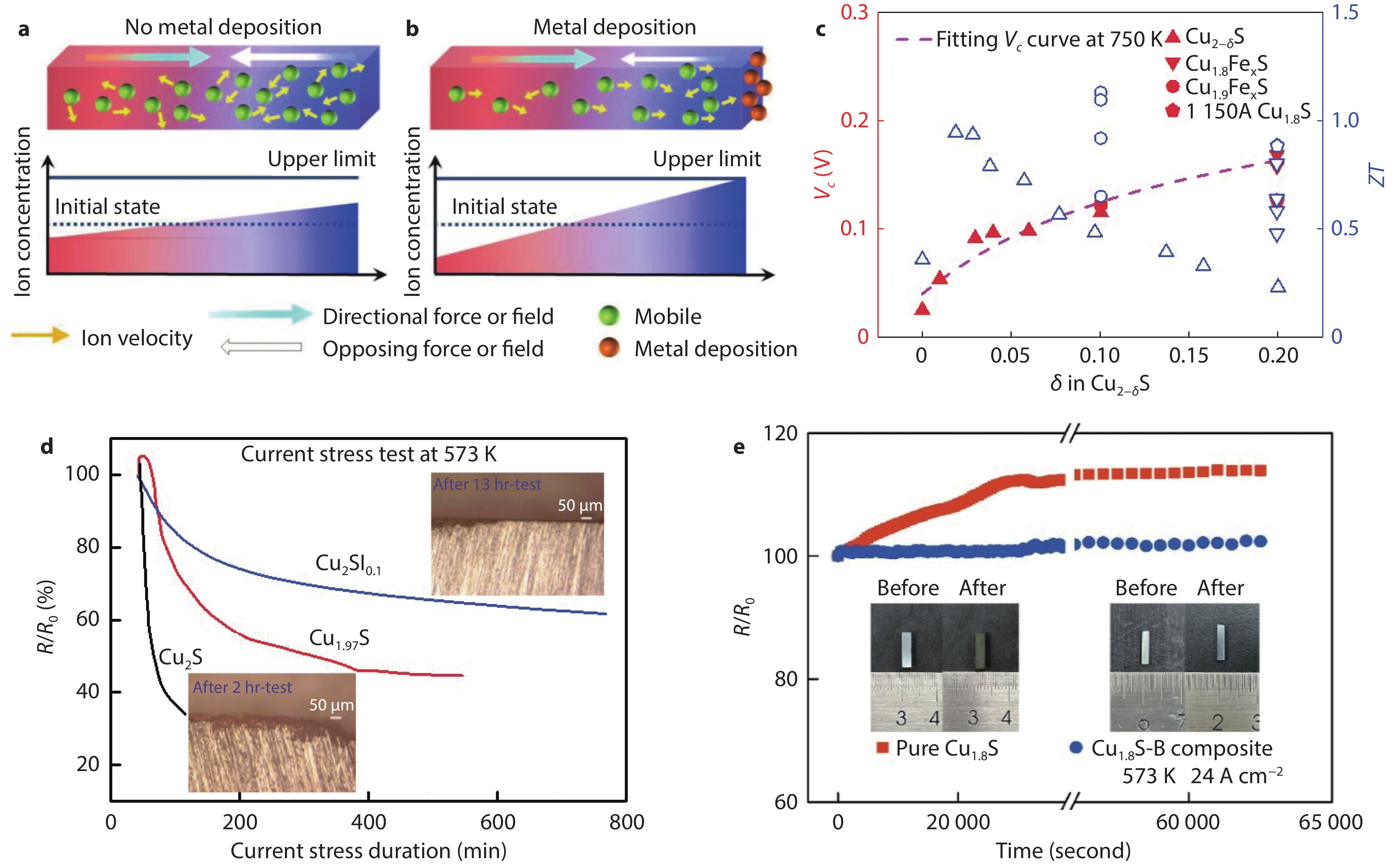

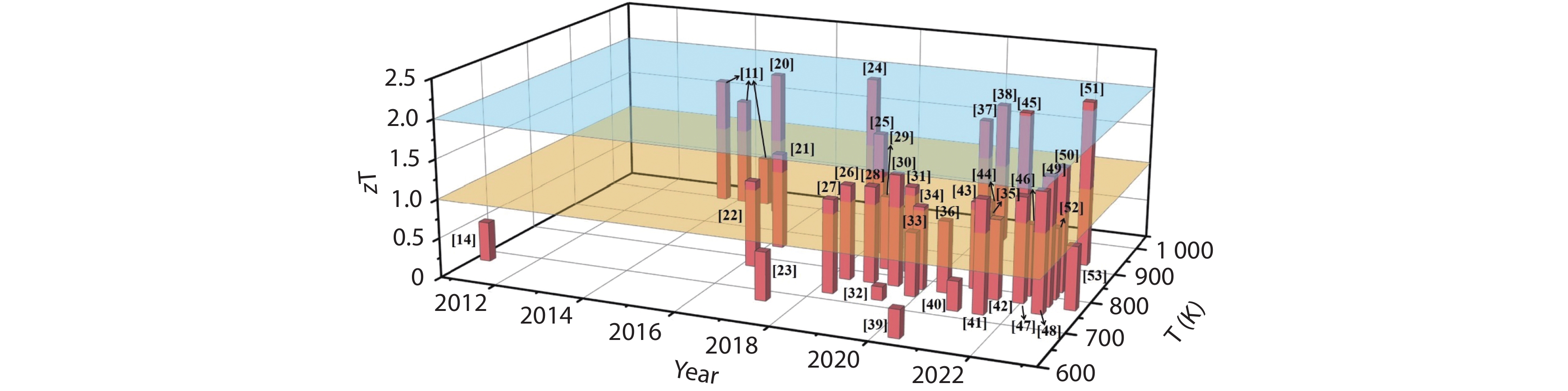

Figure 1.

Dimensionless figure of merit ZT for binary copper sulfide-based thermoelectric materials as a function of temperature and year. The data were taken from[11, 14, 20-53].

-

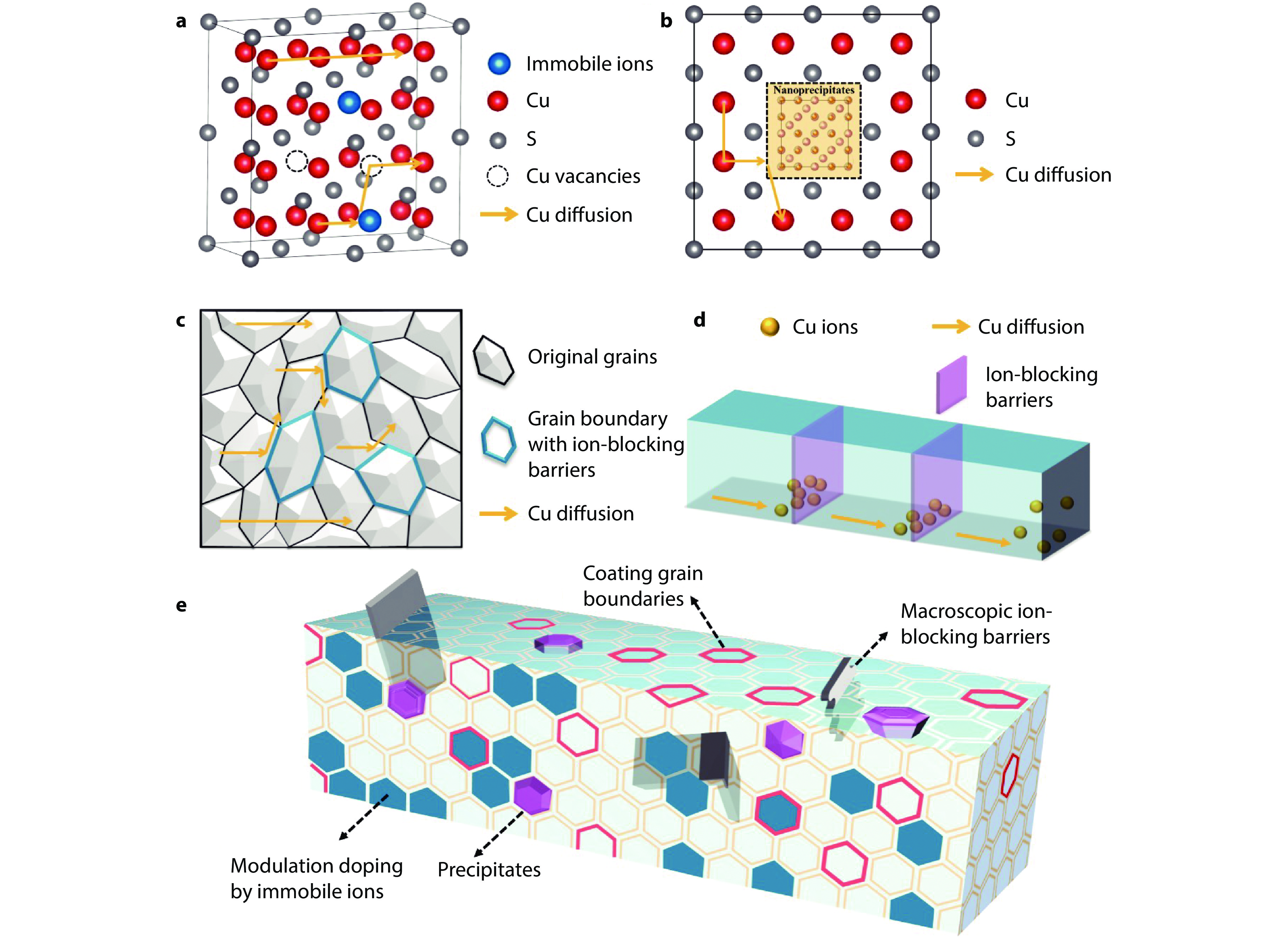

Figure 2.

Schematic of a steady state of copper sulfides without ion directional long-range migration (and without metal deposition) and b continuous metal deposition (or other decomposition), if the local Cu ion concentration reaches a critical level for the materials[54]. Copyright 2018, Springer Nature. c Critical voltage (Vc) and ZT at 750 K as a function of Cu vacancy content (δ) for Cu2-δS (0≤δ≤0.2), Cu1.8FexS (x=0.024, 0.036, 0.048 and 0.064), Cu1.9FexS (x=

0.0125 ,0.0225 and0.0325 ) and high-current SPSed Cu1.8S specimens are included for comparison. d Time dependence of relative electrical resistance (R/R0) for the pure Cu2S, Cu1.97S and Cu2SI0.1 samples under a large current density (12 A cm−2) at 573 K [38]. Copyright 2020, Elsevier. e R/R0 of Cu1.8S and Cu1.8S-B bulk composite as a function of time under a current density 12 A cm−2 at 573 K[47]. Copyright 2022, Elsevier. -

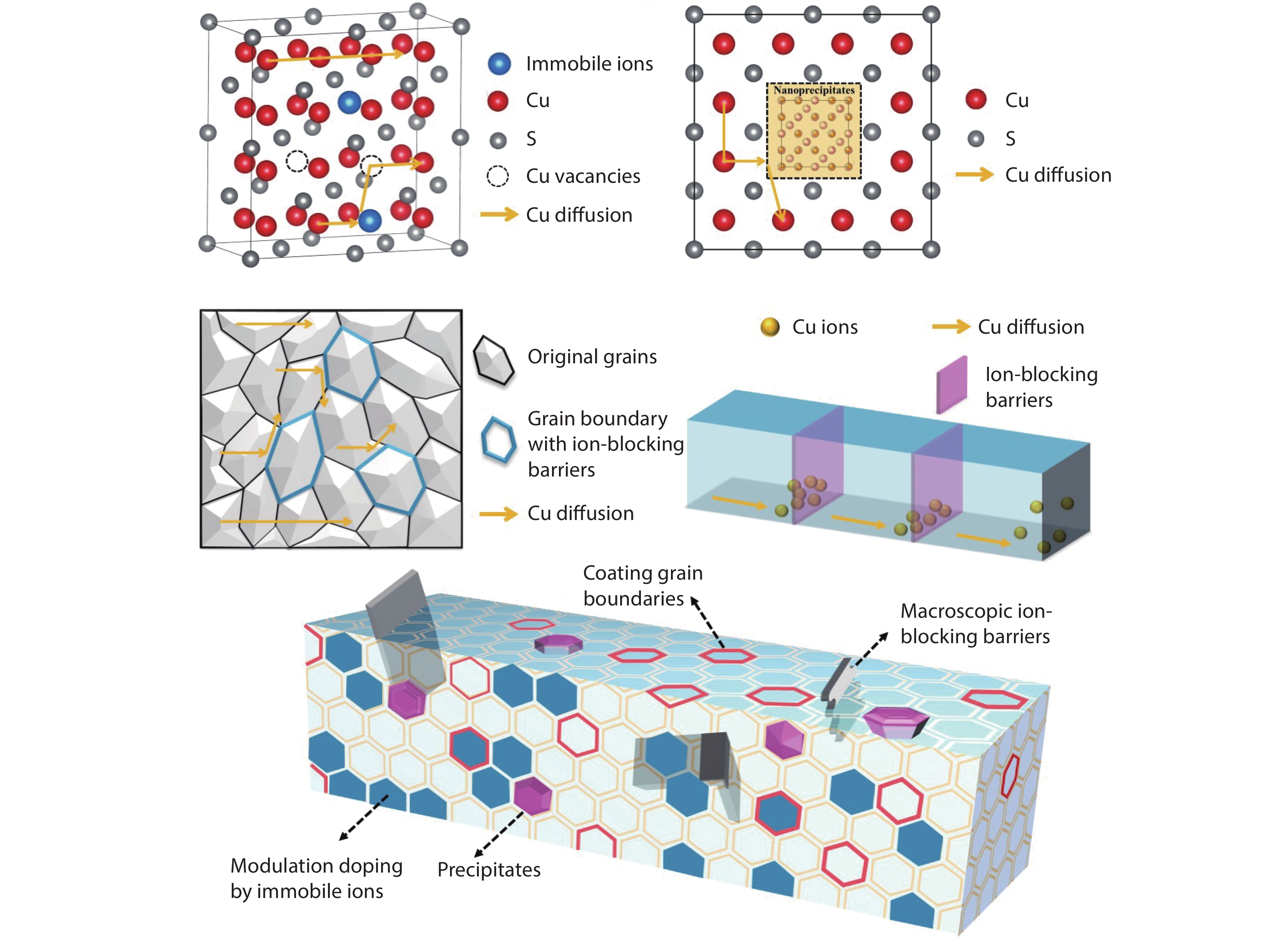

Figure 3.

Multiscale ion-blocking barriers in the copper sulfides. Sketch map of Cu ion diffusion in the framework of copper sulfides at high temperature when a atomic-scale defects (immobile ions or Cu vacancies), b nanoprecipitates, c interfacial scale barriers and d macroscopic partition ion-blocking barriers are introduced. e Schematic of improving stability of copper sulfides by simultaneously introducing multiscale ion-blocking barriers.

Yi-Xin Zhang is a Ph.D student with Prof. Zhen-Hua Ge at Faculty of Materials Science and Engineering at Kunming University of Science and Technology. He received his M.E. degree in Materials Science at Kunming University of Science and Technology. His research focuses on the synthesis and characterization of chalcogenide thermoelectric materials, especially copper sulfides and copper selenides.

Yi-Xin Zhang is a Ph.D student with Prof. Zhen-Hua Ge at Faculty of Materials Science and Engineering at Kunming University of Science and Technology. He received his M.E. degree in Materials Science at Kunming University of Science and Technology. His research focuses on the synthesis and characterization of chalcogenide thermoelectric materials, especially copper sulfides and copper selenides.  Zhen-Hua Ge is a full professor at Kunming University of Science and Technology. He received his Ph.D. degree in 2013 from University of Science and Technology Beijing, China. And he worked as post-doctoral researcher at University of South Florida and Southern University of Science and Technology from February 2013 to July 2015. His research interests focus on synthesis and properties improvements of thermoelectric materials, especially for sulfides thermoelectric materials.

Zhen-Hua Ge is a full professor at Kunming University of Science and Technology. He received his Ph.D. degree in 2013 from University of Science and Technology Beijing, China. And he worked as post-doctoral researcher at University of South Florida and Southern University of Science and Technology from February 2013 to July 2015. His research interests focus on synthesis and properties improvements of thermoelectric materials, especially for sulfides thermoelectric materials.

DownLoad:

DownLoad: