| Citation: | Fu-Hua Sun, Jun Tan, Hezhang Li, Qin Li, Jun Pei, Xinyu Wang. Exploring electrical property improvement for thermoelectric sulfides[J]. Materials Lab, 2024, 3(1): 202300. doi: 10.54227/mlab.20230012 |

Exploring electrical property improvement for thermoelectric sulfides

-

Abstract

Metal sulfides have been the subject of extensive research as a promising candidate in the study of thermoelectric energy transfer due to their eco-friendly abundance and similarities in chemical and structural properties with tellurides and selenides. Their intrinsically low thermal conductivity decouples the intercorrelated thermoelectric parameters that comprise the figure merit of

ZT -

Keywords:

- Electrical property /

- Power factor /

- Sulfides /

- Thermoelectric

-

-

References

1. Q. Yan, M. G. Kanatzidis, Nat. Mater., 2022, 21, 503 2. J. Pei, B. Cai, H. L. Zhuang, J. F. Li, Nat. Sci. Rev., 2020, 7, 1856 3. H. Wang, R. Gurunathan, C. Fu, R. Cui, T. Zhu, G. J. Snyder, Mater. Adv., 2022, 3, 734 4. Y. Zheng, T. J. Slade, L. Hu, X. Y. Tan, Y. Luo, Z. Z. Luo, J. Xu, Q. Yan, M. G. Kanatzidis, Chem. Soc Rev., 2021, 50, 9022 5. C. L. Hu, K. Y. Xia, C. G. Fu, X. B. Zhao, T. J. Zhu, Energy Environ. Sci., 2022, 15, 1406 6. O. Caballero-Calero, J. R. Ares, M. Martin-Gonzalez, Adv. Sustain. Syst., 2021, 5, 2100095 7. P. Lemoine, V. P. Kumar, G. Guelou, V. Nassif, B. Raveau, E. Guilmeau, Chem. Mater., 2020, 32, 830 8. Z. H. Ge, X. Chong, D. Feng, Y. X. Zhang, Y. Qiu, L. Xie, P. W. Guan, J. Feng, J. He, Mater. Today Phys., 2019, 8, 71 9. F. H. Sun, J. F. Dong, H. C. Tang, P. P. Shang, H. L. Zhuang, H. H. Hu, C. F. Wu, Y. Pan, J. F. Li, Nano Energy, 2019, 57, 835 10. H. Y. Xie, X. L. Su, Y. G. Yan, W. Liu, L. J. Chen, J. F. Fu, J. H. Yang, C. Uher, X. F. Tang, NPG Asia Mater., 2017, 9, e390 11. H. Wang, S. Zheng, H. Wu, X. Xiong, Q. Xiong, H. Wang, Y. Wang, B. Zhang, X. Lu, G. Han, G. Wang, X. Zhou, Small, 2022, 18, e2104592 12. I. Siloi, P. Gopal, S. Curtarolo, M. B. Nardelli, P. Vaqueiro, M. Fornari, ACS Appl. Energ. Mater., 2019, 2, 8068 13. K. P. Zhao, P. F. Qiu, Q. F. Song, A. B. Blichfeld, E. Eikeland, D. D. Ren, B. H. Ge, B. B. Iversen, X. Shi, L. D. Chen, Mater. Today Phys., 2017, 1, 14 14. Q. L. Meng, S. Kong, Z. W. Huang, Y. H. Zhu, H. C. Liu, X. W. Lu, P. Jiang, X. H. Bao, J. Mater. Chem. A, 2016, 4, 12624 15. D. S. Nkemeni, Z. Yang, S. Y. Lou, G. H. Li, S. M. Zhou, J. Alloy Compd., 2021, 878, 160128 16. H. C. Tang, H. L. Zhuang, B. W. Cai, Asfandiyar, J. F. Dong, F. H. Sun, J. F. Li, J. Mater. Chem. C, 2019, 7, 4026 17. Z. H. Hou, D. Y. Wang, T. Hong, Y. X. Qin, S. Peng, G. T. Wang, J. F. Wang, X. Gao, Z. W. Huang, L. D. Zhao, J. Phys. Chem. Solids, 2021, 148, 109640 18. M. Y. Li, Y. Liu, Y. Zhang, C. Chang, T. Zhang, D. W. Yang, K. Xiao, J. Arbiol, M. Ibanez, A. Cabot, Chem. Eng. J., 2022, 433, 133837 19. Y. X. Qin, T. Hong, B. C. Qin, D. Y. Wang, W. K. He, X. Gao, Y. Xiao, L. D. Zhao, Adv. Funct. Mater., 2021, 31, 2102185 20. Y. X. Qin, Y. Xiao, D. Y. Wang, B. C. Qin, Z. W. Huang, L. D. Zhao, J. Alloy Compd., 2020, 820, 153453 21. M. H. Zhao, C. Chang, Y. Xiao, L. D. Zhao, J. Alloy Compd., 2018, 744, 769 22. W. He, D. Wang, H. Wu, Y. Xiao, Y. Zhang, D. He, Y. Feng, Y. J. Hao, J. F. Dong, R. Chetty, L. Hao, D. Chen, J. Qin, Q. Yang, X. Li, J. M. Song, Y. Zhu, W. Xu, C. Niu, X. Li, G. Wang, C. Liu, M. Ohta, S. J. Pennycook, J. He, J. F. Li, L. D. Zhao, Science, 2019, 365, 1418 23. H. T. Wang, H. Q. Ma, B. Duan, H. Y. Geng, L. Zhou, J. L. Li, X. L. Zhang, H. J. Yang, G. D. Li, P. C. Zhai, ACS Appl. Energ. Mater., 2021, 4, 1610 24. R. Abinaya, S. Harish, S. Ponnusamy, M. Shimomura, M. Navaneethan, J. Archana, Chem. Eng. J., 2021, 416, 128484 25. J. Guo, Y. X. Zhang, Z. Y. Wang, F. S. Zheng, Z. H. Ge, J. C. Fu, J. Feng, Nano Energy, 2020, 78, 105227 26. M. Zhang, C. Zhang, Y. You, H. Xie, H. Chi, Y. Sun, W. Liu, X. Su, Y. Yan, X. Tang, C. Uher, ACS Appl. Mater. Interfaces, 2018, 10, 32344 27. S. Tippireddy, R. Chetty, M. H. Naik, M. Jain, K. Chattopadhyay, R. C. Mallik, J. Phys. Chem. C, 2018, 122, 8735 28. Y. Q. Zhao, Y. Gu, P. A. Zong, L. Pan, L. J. Zhang, K. Koumoto, Y. F. Wang, J. Alloy Compd., 2021, 887, 161338 29. B. L. Du, R. Z. Zhang, M. Liu, K. Chen, H. F. Zhang, M. J. Reece, J. Mater. Chem. C, 2019, 7, 394 30. T. Tanishita, K. Suekuni, H. Nishiate, C. H. Lee, M. Ohtaki, Phys. Chem. Chem. Phys., 2020, 22, 2081 31. Y. B. Yang, P. Z. Ying, J. Z. Wang, X. L. Liu, Z. L. Du, Y. M. Chao, J. L. Cui, J. Mater. Chem. A, 2017, 5, 18808 32. T. Deng, T. R. Wei, Q. Song, Q. Xu, D. Ren, P. Qiu, X. Shi, L. Chen, RSC Adv., 2019, 9, 7826 33. J. Y. Hwang, J. Y. Ahn, K. H. Lee, S. W. Kim, J. Alloy Compd., 2017, 704, 282 34. Y. D. Lang, L. Pan, C. C. Chen, Y. F. Wang, J. Electron. Mater., 2019, 48, 4179 35. B. Ge, Z. Shi, C. Zhou, J. Hu, G. Liu, H. Xia, J. Xu, G. Qiao, J. Alloy Compd., 2019, 809, 151717 36. J. D. Burnett, O. Gourdon, K. G. S. Ranmohotti, N. J. Takas, H. Djieutedjeu, P. F. P. Poudeu, J. A. Aitken, Mater. Chem. Phys., 2014, 147, 17 37. P. Mangelis, P. Vaqueiro, J. C. Jumas, I. da Silva, R. I. Smith, A. V. Powell, J. Solid State Chem., 2017, 251, 204 38. J.-H. Kim, D.-Y. Chung, D. Bilc, S. Loo, J. Short, S. D. Mahanti, T. Hogan, M. G. Kanatzidis, Chem. Mater., 2005, 17, 3606 39. B. Jabar, F. Li, Z. Zheng, A. Mansoor, Y. Zhu, C. Liang, D. Ao, Y. Chen, G. Liang, P. Fan, W. Liu, Nat. Commun., 2021, 12, 7192 40. F. Li, M. Ruan, B. Jabar, C. B. Liang, Y. X. Chen, D. W. Ao, Z. H. Zheng, P. Fan, W. S. Liu, Nano Energy, 2021, 88, 106273 41. Q. R. Tao, F. C. Meng, Z. K. Zhang, Y. Cao, Y. F. Tang, J. G. Zhao, X. L. Su, C. Uher, X. F. Tang, Mater. Today Phys., 2021, 20, 100472 42. J. B. Labégorre, A. Virfeu, A. Bourhim, H. Willeman, T. Barbier, F. Appert, J. Juraszek, B. Malaman, A. Huguenot, R. Gautier, V. Nassif, P. Lemoine, C. Prestipino, E. Elkaim, L. Pautrot-d'Alençon, T. Le Mercier, A. Maignan, R. Al Rahal Al Orabi, E. Guilmeau, Adv. Funct. Mater., 2019, 29, 1904112 43. F. G. Cai, R. Dong, W. Sun, X. B. Lei, B. Yu, J. Chen, L. Yuan, C. Wang, Q. Y. Zhang, Chem. Mater., 2021, 33, 6003 44. C. Bourges, Y. Bouyrie, A. R. Supka, R. Al Rahal Al Orabi, P. Lemoine, O. I. Lebedev, M. Ohta, K. Suekuni, V. Nassif, V. Hardy, R. Daou, Y. Miyazaki, M. Fornari, E. Guilmeau, J. Am. Chem. Soc., 2018, 140, 2186 45. G. Guelou, V. P. Kumar, A. Bourhim, P. Lemoine, B. Raveau, A. Supka, O. I. Lebedev, R. A. Al Orabi, M. Fornari, K. Suekuni, E. Guilmeau, ACS Appl. Energ. Mater., 2020, 3, 4180 46. C. Bourges, R. A. Al Orabi, Y. Miyazaki, J. Alloy Compd., 2020, 826, 154240 47. K. Hashikuni, K. Suekuni, K. Watanabe, Y. Bouyrie, M. Ohta, M. Ohtaki, T. Takabatake, J. Solid State Chem., 2018, 259, 5 48. P. Balaz, M. Hegedus, M. Reece, R. Z. Zhang, T. C. Su, I. Skorvanek, J. Briancin, M. Balaz, M. Mihalik, M. Tesinsky, M. Achimovicova, J. Electron. Mater., 2019, 48, 1846 49. H. C. Tang, F. H. Sun, J. F. Dong, Asfandiyar, H. L. Zhuang, Y. Pan, J. F. Li, Nano Energy, 2018, 49, 267 50. Y. He, P. Lu, X. Shi, F. Xu, T. Zhang, G. J. Snyder, C. Uher, L. Chen, Adv. Mater., 2015, 27, 3639 51. H. Hu, H. L. Zhuang, Y. Jiang, J. Shi, J. W. Li, B. Cai, Z. Han, J. Pei, B. Su, Z. H. Ge, B. P. Zhang, J. F. Li, Adv. Mater., 2021, 33, e2103633 52. D. P. Weller, D. T. Morelli, Front. Electro. Mater., 2022, 2, 913280 53. G. Guelou, P. Lemoine, B. Raveau, E. Guilmeau, J. Mater. Chem. C, 2021, 9, 773 54. S. Q. Qu, J. Zhao, Z. M. Jiang, D. Q. Jiang, Y. G. Wang, Mater. Chem. Front., 2021, 5, 1283 -

Rights and permissions

This is an open access article under the terms of the Creative Commons Attribution License, which permits use, distribution and reproduction in any medium, provided the original work is properly cited.

Information

Article Metrics

-

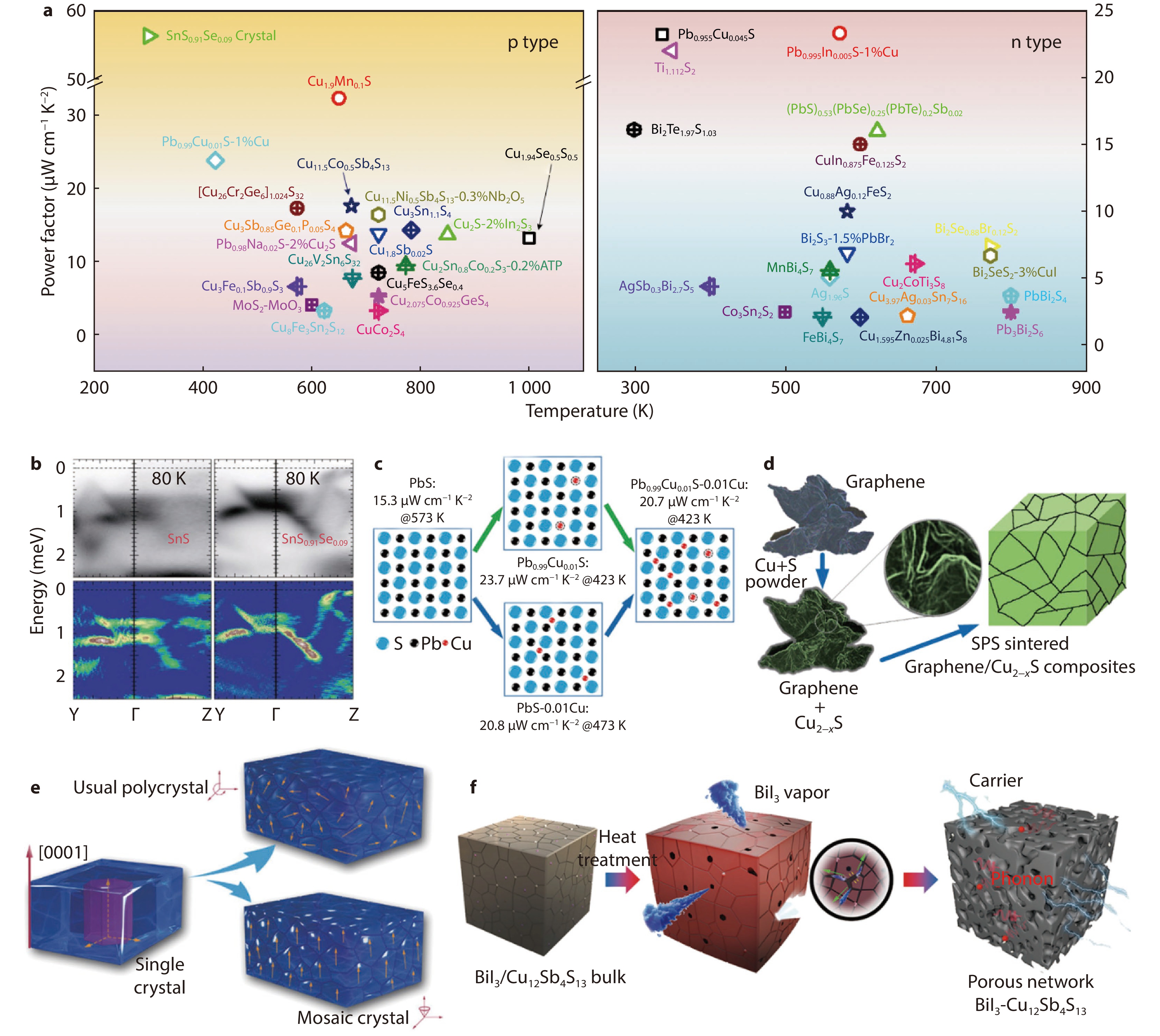

Figure 1.

Progressive overview of structural merits and performance-enhanced strategies in sulfur-based bulks and bottom-up composite.[7-12] Copyright 2019, American Chemical Society; Copyright 2019, Elsevier Ltd.; Copyright 2018, Elsevier Ltd.; Copyright 2017, The Authors; Copyright 2021, Wiley-VCH GmbH; Copyright 2019, American Chemical Society.

-

Figure 2.

a Peak PF values in sulfur-based TE materials. There are two breakdowns: p-type and n-type binary copper[13-16], lead[17-21], tin[22], silver[23], molybdenum[24], bismuth[25] and titanium[26] sulfides, ternary Cu-[9, 11, 27-36], Co-[37] and Bi-based[38-43] sulfides, and polysulfides.[44-48] TE properties have been unfolded, and the current maximum value is 56.3 μW cm−1 K−2 at 300 K in p-type SnS0.91Se0.09 crystal.[22] b Electronic band structures for SnS1-xSex (x = 0, 0.09).[22] Copyright 2019, The Authors, AAAS. c Roadmaps toward high PF in p-type PbS compounds via compositing Cu.[19] Copyright 2021, Wiley-VCH GmbH. d Schematic illustration of the process for fabricating graphene/Cu2-xS composites.[49] Copyright 2018, Elsevier Ltd. e Structural characteristics among a single crystal, usual polycrystal and mosaic crystal.[50] Copyright 2015, Wiley-VCH Verlag GmbH & Co. kGaA, Weinheim. f The progress of porous network-structured Cu12Sb4S13.[51] Copyright 2021, Wiley-VCH GmbH.

Fu-Hua Sun is currently an associate professor of Institute for Advanced Materials at Hubei Normal University, China. He received his Ph.D. degree from Tsinghua University in 2019. He worked as a postdoctoral research fellow at Wuhan University of Technology (2020-2022). His current research focuses on the synthesis of nano-bulk sulfur-based materials and their applications in thermoelectric.

Fu-Hua Sun is currently an associate professor of Institute for Advanced Materials at Hubei Normal University, China. He received his Ph.D. degree from Tsinghua University in 2019. He worked as a postdoctoral research fellow at Wuhan University of Technology (2020-2022). His current research focuses on the synthesis of nano-bulk sulfur-based materials and their applications in thermoelectric.  Hezhang Li received his Ph.D. degree from Tohoku University, Japan in 2022 and then worked in National Institute for Materials Science (NIMS), Japan as a postdoc researcher from April, 2022 to February 2023. He is now a postdoctoral researcher at Tsinghua University, China. His research focuses on the calculation of electronic structure, crystal structure analysis and the transport properties of Heusler alloys and other thermoelectric materials.

Hezhang Li received his Ph.D. degree from Tohoku University, Japan in 2022 and then worked in National Institute for Materials Science (NIMS), Japan as a postdoc researcher from April, 2022 to February 2023. He is now a postdoctoral researcher at Tsinghua University, China. His research focuses on the calculation of electronic structure, crystal structure analysis and the transport properties of Heusler alloys and other thermoelectric materials.

DownLoad:

DownLoad: