| Citation: | Xiang-Xi He, Jia-Hua Zhao, Wei-Hong Lai, Zhuo Yang, Yun Gao, et al. Challenges and Applications of Flexible Sodium Ion Batteries. Materials Lab 2022, 1, 210001. doi: 10.54227/mlab.20210001 |

Challenges and Applications of Flexible Sodium Ion Batteries

-

Abstract

Sodium-ion batteries are considered to be a future alternative to lithium-ion batteries because of their low cost and abundant resources. In recent years, the research of sodium-ion batteries in flexible energy storage systems has attracted widespread attention. However, most of the current research on flexible sodium ion batteries is mainly focused on the preparation of flexible electrode materials. In this paper, the challenges faced in the preparation of flexible electrode materials for sodium ion batteries and the evaluation of device flexibility is summarized. Several important parameters including cycle-calendar life, energy/power density, safety, flexible, biocompatibility and multifunctional intergration of current flexible sodium ion batteries will be described mainly from the application point of view. Finally, the promising current applications of flexible sodium ion batteries are summarized.

-

Keywords:

- Flexible sodium-ion batteries /

- Solid-State batteries /

- Dual-Ion Battery /

- Stretchable /

- Self-healing /

- Self-charging /

- Textile.

-

-

References

1. a) L. Li, Z. Wu, S. Yuan, X.-b. Zhang, Energy Environ. Sci. 2014, 7, 2101.; b) S.-Y. Lee, K.-H. Choi, W.-S. Choi, Y. H. Kwon, H.-R. Jung, H.-C. Shin, J. Y. Kim, Energy Environ. Sci. 2013, 6, 2414 2. X. Wang, X. Lu, B. Liu, Di Chen, Y. Tong, G. Shen, Adv. Mater., 2014, 26, 4763 3. a) G. Zhou, F. Li, H.-M. Cheng, Energy Environ. Sci. 2014, 7, 1307.; b) H. Gwon, J. Hong, H. Kim, D.-H. Seo, S. Jeon, K. Kang, Energy Environ. Sci. 2014, 7, 538; c) L. Wang, Di Chen, K. Jiang, G. Shen, Chemical Society Reviews 2017, 46, 6764 4. a) Z. Yang, X. Liu, X. He, W. Lai, L. Li, Y. Qiao, S. Chou, M. Wu, Adv. Funct. Mater. 2020, 31, 2006457.; b) Y. Gao, H. Zhang, X. Liu, Z. Yang, X. He, L. Li, Y. Qiao, S. Chou, Adv. Ener. Mater. 2021, 11, 2101751 5. A. Sumboja, J. Liu, W. G. Zheng, Y. Zong, H. Zhang, Z. Liu, Chemical Society Reviews, 2018, 47, 5919 6. H. Li, X. Zhang, Z. Zhao, Z. Hu, X. Liu, G. Yu, Energy Storage Mater., 2020, 26, 83 7. T. Jin, Q. Q. Han, L. F. Jiao, Adv. Mater., 2020, 32, 1806304 8. M. Chen, D. Cortie, Z. Hu, H. Jin, S. Wang, Q. Gu, W. Hua, E. Wang, W. Lai, L. Chen, et al, Adv. Energy Mater., 2018, 8, 1800944 9. H. Shi, G. Wen, Y. Nie, G. Zhang, H. Duan, Nanoscale, 2020, 12, 5261 10. C. Wu, X. H. Zeng, P. G. He, L. B. Chen, W. F. Wei, Advanced Materials Interfaces, 2018, 5, 1701080 11. Y. Yao, M. L. Chen, R. Xu, S. F. Zeng, H. Yang, S. F. Ye, F. F. Liu, X. J. Wu, Y. Yu, Adv. Mater., 2018, 30, 1805234 12. D. Z. Kong, Y. Wang, Y. von Lim, S. Z. Huang, J. Zhang, B. Liu, T. P. Chen, H. Y. Yang, Nano Energy, 2018, 49, 460 13. H. Zhang, Y. Gao, X.-H. Liu, Z. Yang, X.-X. He, L. Li, Y. Qiao, W.-H. Chen, R.-H. Zeng, Y. Wang, et al, Adv. Funct. Mater., 2021, 32, 2107718 14. H. Li, Z. Tang, Z. Liu, C. Zhi, Joule, 2019, 3, 613 15. J. Chang, Q. Huang, Y. Gao, Z. Zheng, Adv. Mater., 2021, 33, 2004419 16. C. Zhao, Y. Lu, L. Chen, Y.-S. Hu, InfoMat, 2020, 2, 126 17. X.-X. He, X.-H. Liu, Z. Yang, H. Zhang, L. Li, G. Xu, Y. Qiao, S.-L. Chou, M. Wu, Electrochemistry Communications, 2021, 128, 107067 18. S. N. Liu, Z. G. Luo, G. Y. Tian, M. N. Zhu, Z. Y. Cai, A. Q. Pan, S. Q. Liang, J. Power Sources, 2017, 363, 284 19. Z. H. Li, W. Shen, C. Wang, Q. J. Xu, H. M. Liu, Y. G. Wang, Y. Y. Xia, J. Mater. Chem. A, 2016, 4, 17111 20. K. Wang, Y. Huang, M. Y. Wang, M. Yu, Y. D. Zhu, J. S. Wu, Carbon, 2017, 125, 375 21. C. S. Zhou, S. X. Fan, M. X. Hu, J. M. Lu, J. Li, Z. H. Huang, F. Y. Kang, R. T. Lv, J. Mater. Chem. A, 2017, 5, 15517 22. S. A. Liu, Z. Y. Cai, J. Zhou, M. N. Zhu, A. Q. Pan, S. Q. Liang, J. Mater. Chem. A, 2017, 5, 9169 23. Z. H. Zhao, X. D. Hu, H. Q. Wang, M. Y. Ye, Z. Y. Sang, H. M. Ji, X. L. Li, Y. J. Dai, Nano Energy, 2018, 48, 526 24. X.-X. He, J.-H. Zhao, W.-H. Lai, R. Li, Z. Yang, C.-m. Xu, Y. Dai, Y. Gao, X.-H. Liu, L. Li, et al, ACS Appl. Mater. Interfaces, 2021, 13, 44358 25. H. Zhu, C. Y. Wang, C. Y. Li, L. L. Guan, H. G. Pan, M. Yan, Y. Z. Jiang, Carbon, 2018, 130, 145 26. X. Z. Sun, C. L. Wang, Y. Gong, L. Gu, Q. W. Chen, Y. Yu, Small, 2018, 14, 1802218 27. X. J. Wang, K. Z. Cao, Y. J. Wang, L. F. Jiao, Small, 2017, 13(29), 1700623 28. T. Liu, K. C. Kim, B. Lee, Z. Chen, S. Noda, S. S. Jang, S. W. Lee, Energy Environ. Sci., 2017, 10, 205 29. X. W. Wang, H. P. Guo, J. Liang, J. F. Zhang, B. Zhang, J. Z. Wang, W. B. Luo, H. K. Liu, S. X. Dou, Adv. Funct. Mater., 2018, 28, 1801016 30. M. H. Chen, D. L. Chao, J. L. Liu, J. X. Yan, B. W. Zhang, Y. Z. Huang, J. Y. Lin, Z. X. Shen, Adv. Funct. Mater., 2017, 27, 1606232 31. J. T. Xu, M. Wang, N. P. Wickramaratne, M. Jaroniec, S. X. Dou, L. M. Dai, Adv. Mater., 2015, 27(12), 2042−2048 32. Y. H. Liu, A. Y. Zhang, C. F. Shen, Q. Z. Liu, X. A. Cao, Y. Q. Ma, L. A. Chen, C. Lau, T. C. Chen, F. Wei, et al, ACS Nano, 2017, 11, 5530 33. N. Sun, Y. Guan, Y.-T. Liu, Q. Zhu, J. Shen, H. Liu, S. Zhou, B. Xu, Carbon, 2018, 137, 475 34. Y. Liu, Y. Z. Yang, X. Z. Wang, Y. F. Dong, Y. C. Tang, Z. F. Yu, Z. B. Zhao, J. S. Qiu, ACS Appl. Mater. Interfaces, 2017, 9, 15484 35. T. Y. Liu, B. Lee, B. G. Kim, M. J. Lee, J. Park, S. W. Lee, Small, 2018, 14, 1801236 36. J. J. He, N. Wang, Z. L. Cui, H. P. Du, L. Fu, C. S. Huang, Z. Yang, X. Y. Shen, Y. P. Yi, Z. Y. Tu, et al, Nat Commun, 2017, 8, 1 37. H. Bian, J. Zhang, M.-F. Yuen, W. Kang, Y. Zhan, D. Y. W. Yu, Z. Xu, Y. Y. Li, J. Power Sources, 2016, 307, 634 38. H. Wang, X. Gao, J. Feng, S. Xiong, Electrochim. Acta, 2015, 182, 769 39. H.-Y. Lu, X.-H. Zhang, F. Wan, D.-S. Liu, C.-Y. Fan, H.-M. Xu, G. Wang, X.-L. Wu, ACS Appl. Mater. Interfaces, 2017, 9, 12518 40. J. Fei, Y. L. Cui, J. Y. Li, Z. W. Xu, J. Yang, R. Y. Wang, Y. Y. Cheng, J. F. Hang, Chemical Communications, 2017, 53, 13165 41. H. Y. Wang, H. Jiang, Y. J. Hu, P. Saha, Q. L. Cheng, C. Z. Li, Chemical Engineering Science, 2017, 174, 104 42. W. N. Ren, H. F. Zhang, C. Guan, C. W. Cheng, Adv. Funct. Mater., 2017, 27, 1702116 43. Y. Zhang, Z. Q. Liu, H. Y. Zhao, Y. P. Du, Rsc Advances, 2016, 6, 1440 44. X. Wei, W. H. Li, J. A. Shi, L. Gu, Y. Yu, ACS Appl. Mater. Interfaces, 2015, 7, 27804 45. Y. Wang, C. Wu, Z. Wu, G. Cui, F. Xie, X. Guo, X. Sun, Chemical Communications, 2018, 54, 9341 46. M. S. Balogun, Y. Luo, F. Y. Lyu, F. X. Wang, H. Yang, H. B. Li, C. L. Liang, M. Huang, Y. C. Huang, Y. X. Tong, ACS Appl. Mater. Interfaces, 2016, 8, 9733 47. P. Nie, L. F. Shen, G. Pang, Y. Y. Zhu, G. Y. Xu, Y. H. Qing, H. Dou, X. G. Zhang, J. Mater. Chem. A, 2015, 3, 16590 48. Y. Bao, Y. P. Huang, X. Song, J. Long, S. Q. Wang, L. X. Ding, H. H. Wang, Electrochim. Acta, 2018, 276, 304 49. H. Tao, L. Xiong, S. Du, Y. Zhang, X. Yang, L. Zhang, Carbon, 2017, 122, 54 50. X. J. Wang, Y. C. Liu, Y. J. Wang, L. F. Jiao, Small, 2016, 12, 4865 51. S. Gao, G. Chen, Y. Dall’Agnese, Y. J. Wei, Z. M. Gao, Y. Gao, Chemistry-a European Journal, 2018, 24, 13535 52. G. S. Chen, X. Yao, Q. C. Cao, S. X. Ding, J. D. He, S. Q. Wang, Materials Letters, 2019, 234, 121 53. Y. L. Pan, X. D. Cheng, Y. J. Huang, L. L. Gong, H. P. Zhang, ACS Appl. Mater. Interfaces, 2017, 9, 35820 54. H. Yin, H.-Q. Qu, Z. Liu, R.-Z. Jiang, C. Li, M.-Q. Zhu, Nano Energy, 2019, 58, 715 55. Q. Chen, S. Sun, T. Zhai, M. Yang, X. Y. Zhao, H. Xia, Adv. Energy Mater., 2018, 8, 1800054 56. X. Q. Xiong, W. Luo, X. L. Hu, C. J. Chen, L. Qie, D. F. Hou, Y. H. Huang, Scientific Reports, 2015, 5, 9254 57. H. Yang, M. Wang, X. W. Liu, Y. Jiang, Y. Yu, Nano Research, 2018, 11, 3844 58. W. Li, R. Bi, G. X. Liu, Y. X. Tian, L. Zhang, ACS Appl. Mater. Interfaces, 2018, 10, 26982 59. C. T. Zhao, C. Yu, M. D. Zhang, Q. Sun, S. F. Li, M. N. Banis, X. T. Han, Q. Dong, J. Yang, G. Wang, et al, Nano Energy, 2017, 41, 66 60. M. L. Mao, C. Y. Cui, M. G. Wu, M. Zhang, T. Gao, X. L. Fan, J. Chen, T. H. Wang, J. M. Ma, C. S. Wang, Nano Energy, 2018, 45, 346 61. M. Zhu, Z. Luo, A. Pan, H. Yang, T. Zhu, S. Liang, G. Cao, Chem. Eng. J., 2018, 334, 2190 62. L. L. Luo, B. Cheng, S. J. Chen, Z. C. Ge, H. T. Zhuo, Materials Letters, 2018, 232, 153 63. C. Deng, S. Zhang, H. Wang, G. Zhang, Nano Energy, 2018, 49, 419 64. T. T. Yu, B. Lin, Q. F. Li, X. H. Wang, W. L. Qu, S. Zhang, C. Deng, Physical Chemistry Chemical Physics, 2016, 18, 26933 65. X. Zhang, J. Zhou, C. Liu, X. Chen, H. Song, J. Mater. Chem. A, 2016, 4, 8837 66. H. R. An, Y. Li, Y. Gao, C. Cao, J. K. Han, Y. Y. Feng, W. Feng, Carbon, 2017, 116, 338 67. N. Q. Tran, T. A. Le, H. Lee, J. Mater. Chem. A, 2018, 6, 17495 68. W. Liu, B. Shi, Y. Wang, Y. Li, H. J. Pei, R. Guo, X. W. Hou, K. Zhu, J. Y. Xie, Chemistryselect, 2018, 3, 5608 69. P. L. Zheng, Z. F. Dai, Y. Zhang, K. N. Dinh, Y. Zheng, H. S. Fan, J. Yang, R. Dangol, B. Li, Y. Zong, et al, Nanoscale, 2017, 9, 14820 70. W. W. Xu, K. N. Zhao, L. Zhang, Z. Q. Xie, Z. Y. Cai, Y. Wang, Journal of Alloys and Compounds, 2016, 654, 357 71. X. X. Ma, L. Chen, X. H. Ren, G. M. Hou, L. N. Chen, L. Zhang, B. B. Liu, Q. Ai, P. C. Si, J. Lou, et al, J. Mater. Chem. A, 2018, 6, 1574 72. Y. H. Liu, A. Y. Zhang, C. F. Shen, Q. Z. Liu, J. S. Cai, X. Cao, C. W. Zhou, Nano Research, 2018, 11, 3780 73. S. Zhang, C. Deng, Y. Meng, J. Mater. Chem. A, 2014, 2, 20538 74. D. Yang, X.-Z. Liao, J. Shen, Y.-S. He, Z.-F. Ma, Journal of Materials Chemistry A, 2014, 2, 6723 75. F. X. Bu, P. T. Xiao, J. D. Chen, M. F. A. Aboud, I. Shakir, Y. X. Xu, J. Mater. Chem. A, 2018, 6, 6414 76. H. Chu, Y. Pei, Z. Cui, C. Steven, P. Dong, P. M. Ajayan, M. X. Ye, J. F. Shen, Nanoscale, 2018, 10, 14697 77. J. Y. Xiang, D. D. Dong, F. S. Wen, J. Zhao, X. Y. Zhang, L. M. Wang, Z. Y. Liu, Journal of Alloys and Compounds, 2016, 660, 11 78. D. L. Chao, C. R. Zhu, X. H. Xia, J. L. Liu, X. Zhang, J. Wang, P. Liang, J. Y. Lin, H. Zhang, Z. X. Shen, et al, Nano Lett., 2015, 15, 565 79. T. C. Yuan, Y. X. Wang, J. X. Zhang, X. J. Pu, X. P. Ai, Z. X. Chen, H. X. Yang, Y. L. Cao, Nano Energy, 2019, 56, 160 80. Y. M. Yin, F. Y. Xiong, C. Y. Pei, Y. A. Xu, Q. Y. An, S. S. Tan, Z. C. Zhuang, J. Z. Sheng, Q. D. Li, L. Q. Mai, Nano Energy, 2017, 41, 452 81. M. Zhou, W. Li, T. T. Gu, K. L. Wang, S. C. Cheng, K. Jiang, Chemical Communications, 2015, 51, 14354 82. T. Yuan, J. F. Ruan, W. M. Zhang, Z. P. Tan, J. H. Yang, Z. F. Ma, S. Y. Zheng, ACS Appl. Mater. Interfaces, 2016, 8, 35114 83. J. F. Ruan, T. Yuan, Y. P. Pang, S. N. Luo, C. X. Peng, J. H. Yang, S. Y. Zheng, Carbon, 2018, 126, 9 84. Y. Zhang, Y. S. Huang, G. H. Yang, F. X. Bu, K. Li, I. Shakir, Y. X. Xu, ACS Appl. Mater. Interfaces, 2017, 9, 15549 85. Y. S. Huang, K. Li, J. J. Liu, X. Zhong, X. F. Duan, I. Shakir, Y. X. Xu, J. Mater. Chem. A, 2017, 5, 2710 86. B. Wang, W. Yuan, X. Zhang, M. Xiang, Y. Zhang, H. Liu, H. Wu, Inorganic Chemistry, 2019, 58(13), 8841−8853 87. S. Wang, L. Xia, Le Yu, L. Zhang, H. Wang, X. W. D. Lou, Adv. Energy Mater., 2016, 6, 1502217 88. Y. W. Wang, N. Xiao, Z. Y. Wang, Y. C. Tang, H. Q. Li, M. L. Yu, C. Liu, Y. Zhou, J. S. Qiu, Carbon, 2018, 135, 187 89. M. L. Sun, Z. Z. Wang, J. F. Ni, L. Li, Adv. Funct.Mater., 30, 1910043 90. B. Long, J. N. Zhang, L. Luo, G. F. Ouyang, M. S. Balogun, S. Q. Song, Y. X. Tong, J. Mater. Chem. A, 2019, 7, 2626 91. S. Choi, D. Lee, G. Kim, Y. Y. Lee, B. Kim, J. Moon, W. Shim, Adv. Funct. Mater., 2017, 27, 1702244 92. K. Zhang, X. Zhang, W. He, W. Xu, G. Xu, X. Yi, X. Yang, J. Zhu, Journal of Materials Chemistry A, 2019, 7, 9890 93. Y. Liu, Y. J. Fang, Z. W. Zhao, C. Z. Yuan, X. W. Lou, Advanced Energy Materials, 2019, 9, 1803052 94. W. Zhang, Y. T. Liu, C. J. Chen, Z. Li, Y. H. Huang, X. L. Hu, Small, 2015, 11, 3822 95. D. Kong, Y. Wang, S. Huang, Y. von Lim, J. Zhang, L. Sun, B. Liu, T. Chen, P. Valdivia y Alvarado, H. Y. Yang, J. Mater. Chem. A, 2019, 7, 12751 96. W. H. Chen, X. X. Zhang, L. W. Mi, C. T. Liu, J. M. Zhang, S. Z. Cui, X. M. Feng, Y. L. Cao, C. Y. Shen, Adv. Mater., 2019, 31, 1806664 97. D. L. Chao, C. H. Lai, P. Liang, Q. L. Wei, Y. S. Wang, C. R. Zhu, G. Deng, V. V. T. Doan Nguyen, J. Y. Lin, L. Q. Mai, et al, Adv. Energy Mater., 2018, 8, 1800058 98. D. Sun, X. B. Zhu, B. Luo, Y. Zhang, Y. G. Tang, H. Y. Wang, L. Z. Wang, Advanced Energy Materials, 2018, 8, 1801197 99. C. Lu, Z. Z. Li, L. H. Yu, L. Zhang, Z. Xia, T. Jiang, W. J. Yin, S. X. Dou, Z. F. Liu, J. Y. Sun, Nano Research, 2018, 11, 4614 100. Z. Sun, Y. Liu, D. Wu, K. Tan, L. Hou, C. Yuan, Nanoscale, 2020, 12, 4119 101. D. L. Guo, J. W. Qin, C. Z. Zhang, M. H. Cao, Crystal Growth & Design, 2018, 18, 3291 102. G. Y. Zhou, Y. E. Miao, Z. X. Wei, L. L. Mo, F. L. Lai, Y. Wu, J. M. Ma, T. X. Liu, Adv. Funct. Mater., 2018, 28, 1804629 103. X. Xu, K. Lin, D. Zhou, Q. Liu, X. Qin, S. Wang, S. He, F. Kang, B. Li, G. Wang, Chem, 2020, 6, 902 104. W. Ling, N. Fu, J. Yue, X.-X. Zeng, Q. Ma, Q. Deng, Y. Xiao, L.-J. Wan, Y.-G. Guo, X.-W. Wu, Adv. Energy Mater., 2020, 10, 1903966 105. Q. Ni, Y. Bai, Y. Li, L. M. Ling, L. M. Li, G. H. Chen, Z. H. Wang, H. X. Ren, F. Wu, C. Wu, Small, 2018, 14, 1702864 106. W. Wang, Q. Xu, H. Liu, Y. Wang, Y. Xia, Journal of Materials Chemistry A, 2017, 5, 8440 107. J. Dong, G. M. Zhang, X. G. Wang, S. Zhang, C. Deng, Journal of Materials Chemistry A, 2017, 5, 18725 108. Y. Wang, D. Z. Kong, S. Z. Huang, Y. M. Shi, M. Ding, Y. V. Lim, T. T. Xu, F. M. Chen, X. J. Li, H. Y. Yang, J. Mater. Chem. A, 2018, 6, 10813 109. B. He, P. Man, Q. Zhang, H. Fu, Z. Zhou, C. Li, Q. Li, L. Wei, Y. Yao, Nano-Micro Letters, 2019, 11, 1 110. F. Tao, L. Qin, Y. Chu, X. Zhou, Q. Pan, ACS Appl. Mater. Interfaces, 2019, 11, 3136 111. Y. H. Zhu, S. Yuan, D. Bao, Y. B. Yin, H. X. Zhong, X. B. Zhang, J. M. Yan, Q. Jiang, Adv. Mater., 2017, 29, 1603719 112. J.-Z. Guo, Z.-Y. Gu, X.-X. Zhao, M.-Y. Wang, X. Yang, Y. Yang, W.-H. Li, X.-L. Wu, Adv. Energy Mater., 2019, 9, 1902056 113. D. L. Guo, J. W. Qin, Z. G. Yin, J. M. Bai, Y. K. Sun, M. H. Cao, Nano Energy, 2018, 45, 136 114. S. Chen, C. Wu, L. Shen, C. Zhu, Y. Huang, K. Xi, J. Maier, Y. Yu, Adv. Mater., 2017, 29, 1700431 115. Y. Yao, Z. Wei, H. Wang, H. Huang, Y. Jiang, X. Wu, X. Yao, Z.-S. Wu, Y. Yu, Adv. Energy Mater., 2020, 10, 1903698 116. H. Ragones, A. Vinegrad, G. Ardel, M. Goor, Y. Kamir, M. M. Dorfman, A. Gladkikh, D. Golodnitsky, J Electrochem Soc, 2019, 167, 070503 117. D. Xie, M. Zhang, Y. Wu, L. Xiang, Y. Tang, Adv. Funct. Mater., 2020, 30, 1906770 118. D. G. Mackanic, T.-H. Chang, Z. Huang, Y. Cui, Z. Bao, Chemical Society Reviews, 2020, 49, 4466 119. C. Y. Chan, Z. Wang, H. Jia, P. F. Ng, L. Chow, B. Fei, Journal of Materials Chemistry A, 2021, 9, 2043 120. H. S. Li, Y. Ding, H. Ha, Y. Shi, L. L. Peng, X. G. Zhang, C. J. Ellison, G. H. Yu, Adv. Mater., 2017, 29, 1700898 121. A. Fakharuddin, H. Li, F. Di Giacomo, T. Zhang, N. Gasparini, A. Y. Elezzabi, A. Mohanty, A. Ramadoss, J. Ling, A. Soultati, et al, Adv. Energy Mater., 2021, 11, 2101443 122. F. Mo, G. Liang, Z. Huang, H. Li, D. Wang, C. Zhi, Adv. Mater., 2020, 32, 1902151 123. Z. W. Xi, X. Zhang, Y. S. Ma, C. Zhou, J. Yang, Y. Q. Wu, X. J. Li, Y. F. Luo, D. Y. Chen, Chemelectrochem, 2018, 5, 3127 124. Z. W. Guo, Y. Zhao, Y. X. Ding, X. L. Dong, L. Chen, J. Y. Cao, C. C. Wang, Y. Y. Xia, H. S. Peng, Y. G. Wang, Chem, 2017, 3, 348 125. D. Zhou, L. Xue, L. Wang, N. Wang, W.-M. Lau, X. Cao, Nano Energy, 2019, 61, 435 126. a) E. J. Lee, T. Y. Kim, S.-W. Kim, S. Jeong, Y. Choi, S. Y. Lee, Energy Environ. Sci. 2018, 11, 1425; b) C. K. Jeong, K.-I. Park, J. H. Son, G.-T. Hwang, S. H. Lee, D. Y. Park, H. E. Lee, H. K. Lee, M. Byun, K. J. Lee, Energy Environ. Sci. 2014, 7, 4035; c) C. Zhang, Y. Fan, H. Li, Y. Li, L. Zhang, S. Cao, S. Kuang, Y. Zhao, A. Chen, G. Zhu et al., ACS Nano 2018, 12, 4803 127. M. Xie, Y. Zhang, M. J. Kraśny, C. Bowen, H. Khanbareh, N. Gathercole, Energy Environ. Sci., 2018, 11, 2919 128. Z. L. Wang, Adv. Mater., 2009, 21, 1311 129. H. He, Y. Fu, T. Zhao, X. Gao, L. Xing, Y. Zhang, X. Xue, Nano Energy, 2017, 39, 590 130. X. Xue, P. Deng, S. Yuan, Y. Nie, B. He, L. Xing, Y. Zhang, Energy Environ. Sci., 2013, 6, 2615 131. X. Xue, S. Wang, W. Guo, Y. Zhang, Z. L. Wang, Nano Lett., 2012, 12, 5048 132. X. Xue, P. Deng, B. He, Y. Nie, L. Xing, Y. Zhang, Z. L. Wang, Adv. Energy Mater., 2014, 4, 1301329 133. A. Ramadoss, B. Saravanakumar, S. W. Lee, Y.-S. Kim, S. J. Kim, Z. L. Wang, ACS Nano, 2015, 9, 4337 134. Q. Zheng, B. Shi, Z. Li, Z. L. Wang, Adv. Sci., 2017, 4, 1700029 -

Rights and permissions

This is an open access article under the terms of the Creative Commons Attribution License, which permits use, distribution and reproduction in any medium, provided the original work is properly cited.

Information

Article Metrics

-

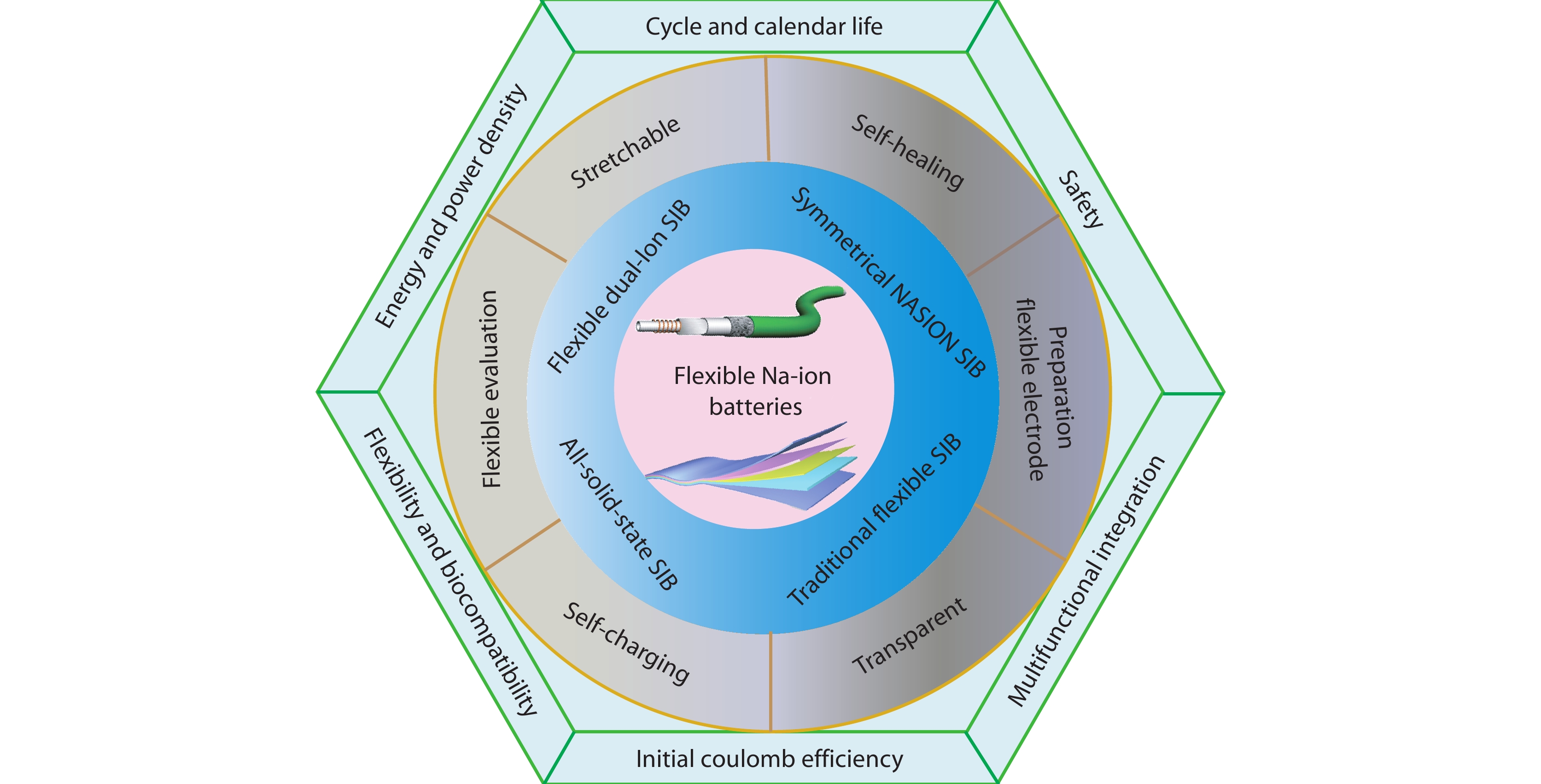

Figure 1.

Challenges and application of flexible sodium ion batteries. Illustrations reproduced with permission. Copyright 2017, Wiley-VCH. Illustrations reproduced with permission[110] Copyright 2017, Elsevier.

-

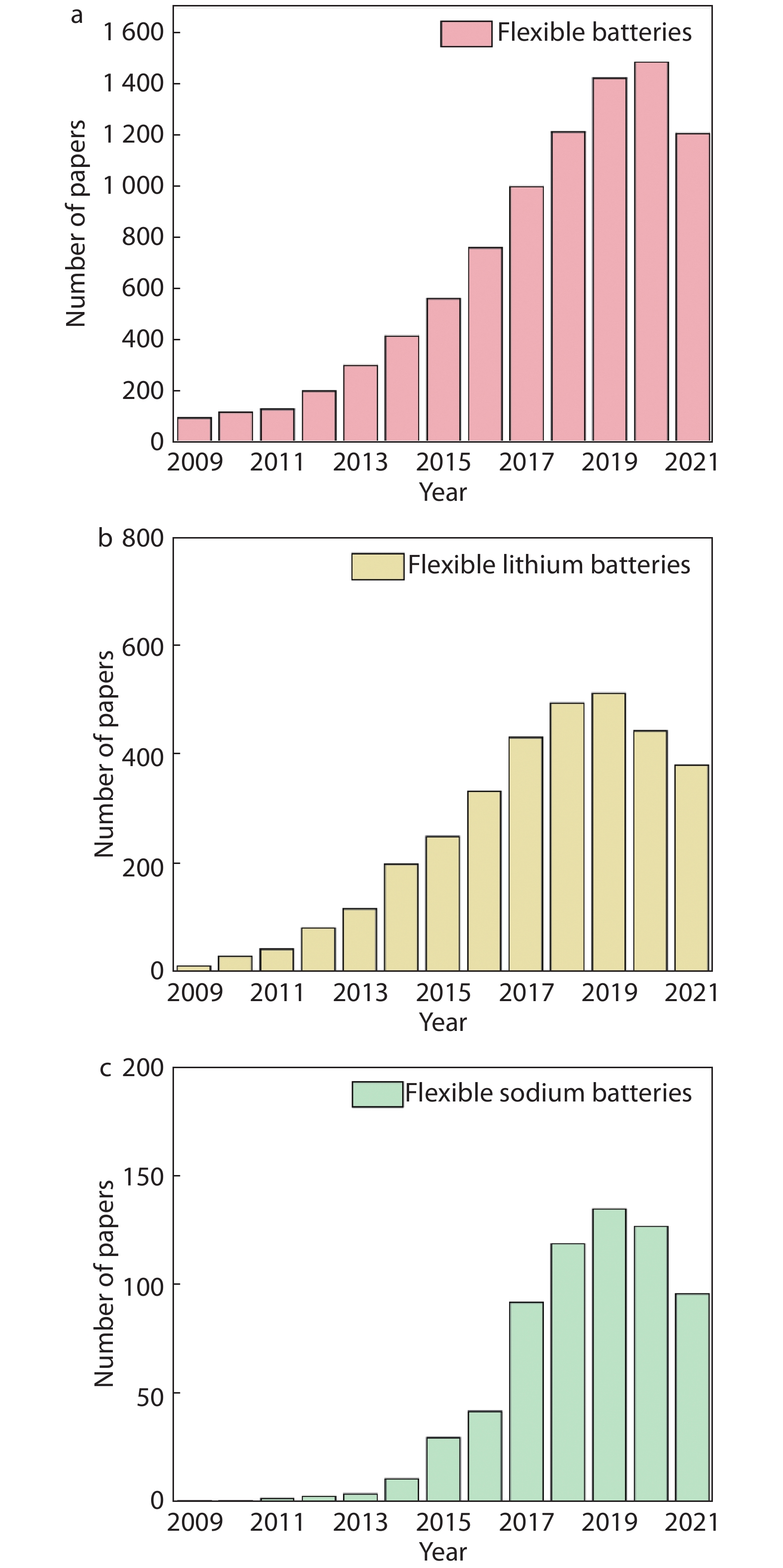

Figure 2.

The trends of "flexible battery", "flexible lithium-ion battery" and "flexible sodium-ion battery" in the past 10 years after "Web of Science".

-

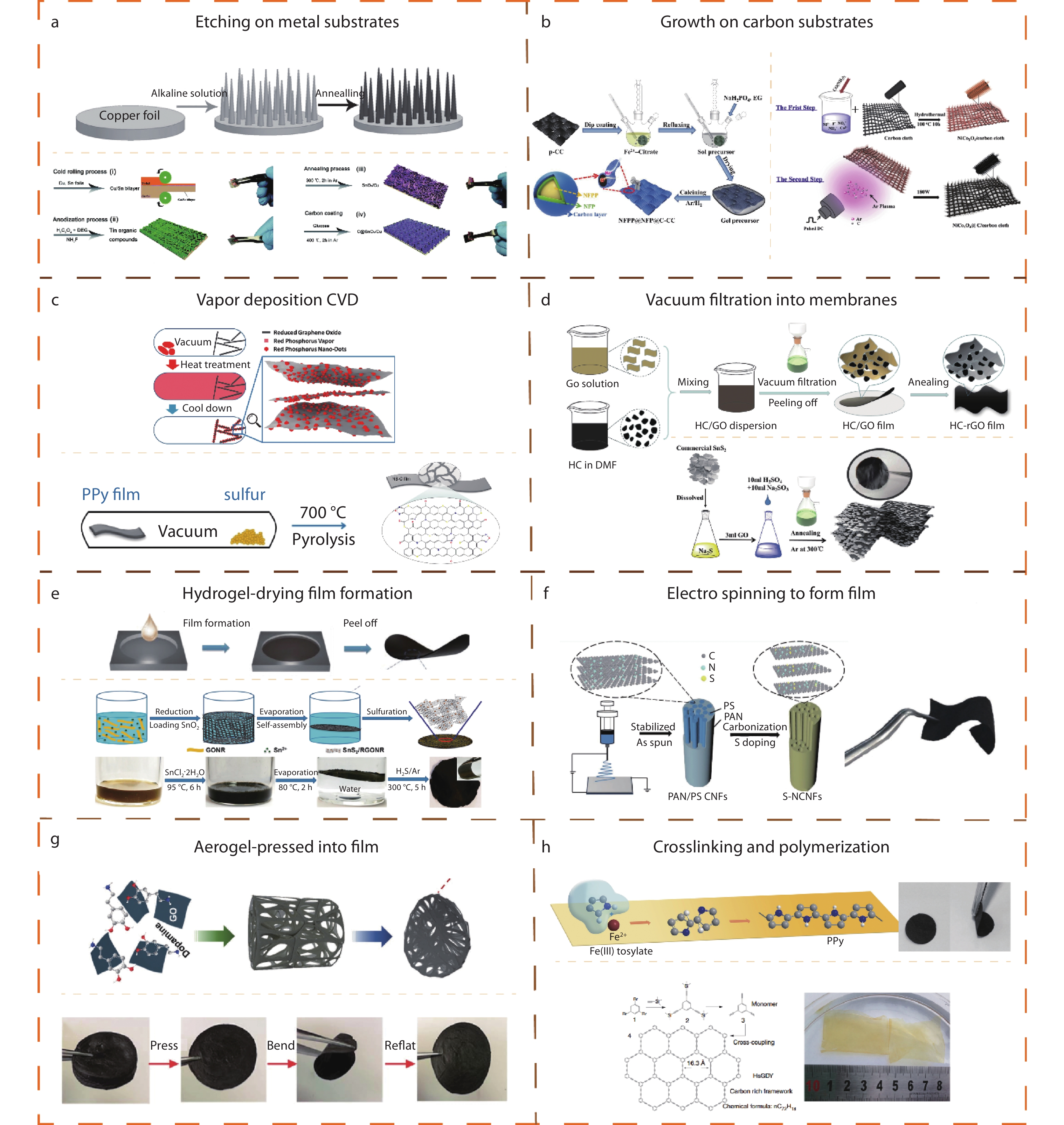

Figure 3.

Preparation of electrode materials for flexible sodium ion batteries: (a) Etching on metal substrate. Reproduced with permission.[12] Copyright 2018, Elsevier. (b) Grown on carbon substare. Reproduced with permission.[20] Copyright 2017, Elsevier. (c) Vapor deposisition Vacuum into membranes. Reproduced with permission.[32]Copyright 2017, American Chemical Society. (d) Vacuum filtration into membranes. Reproduced with permission.[33] Copyright 2018, Elsevier. (e) Hydrogel-drying film formation. Reproduced with permission.[34] Copyright 2017, American Chemical Society. (f) Electrospinning spinning to form film. Reproduced with permission.[26] Copyright 2018, Wiley-VCH. (g) Aerogel-pressed into film. Reproduced with permission.[35] Copyright 2018, Wiley-VCH. (h) Crosslinking and polymerization. Reproduced with permission.[36]. Copyright 2017, Springer Nature.

-

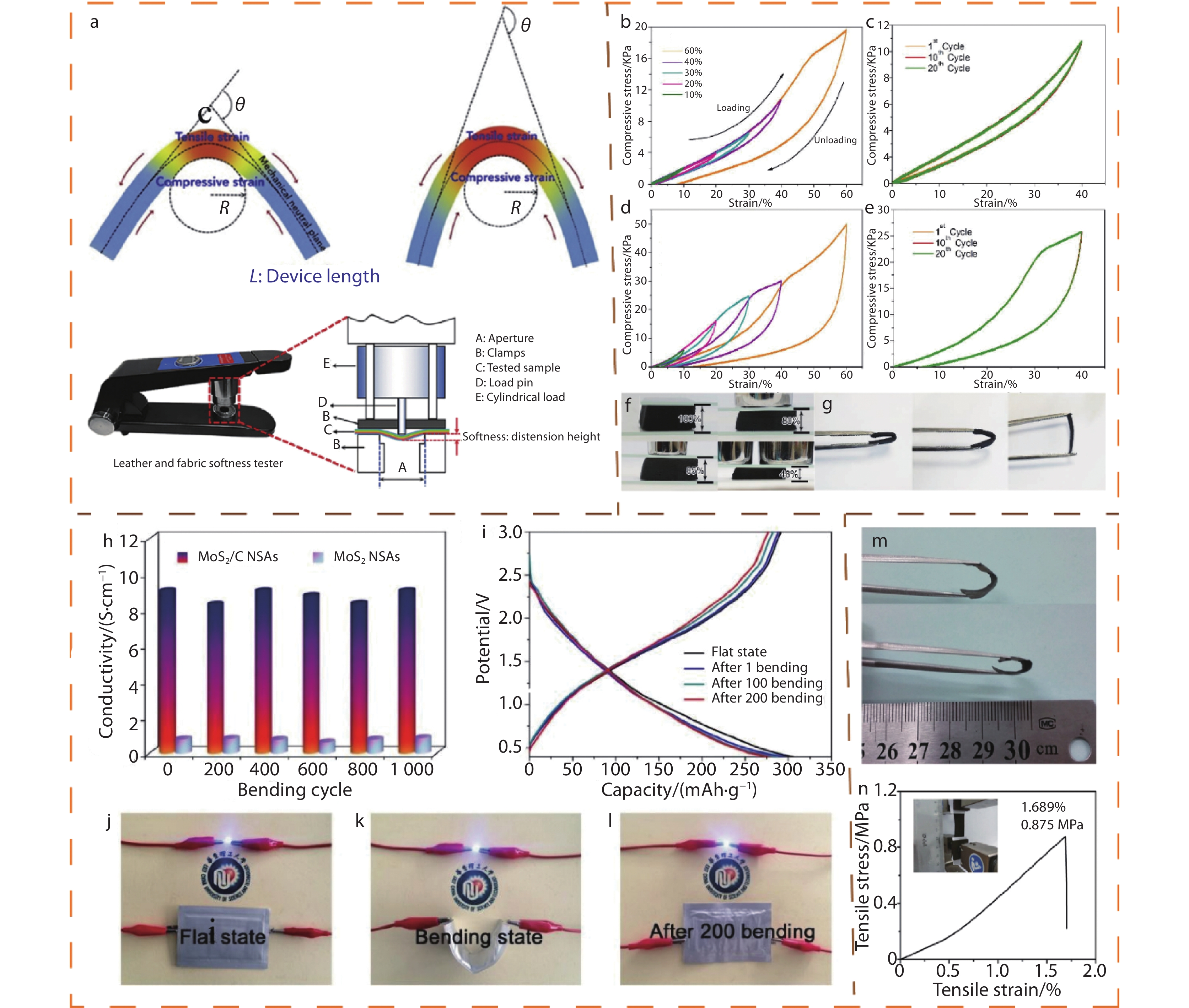

Figure 4.

a) Assessment tools for flexible fiber battery. Reproduced with permission.[14]. Copyright 2019, Elsevier. Compressive stress-strain curves of: b) C-framework and c) MoS2@CF sample. Compressive stress-strain curves of several selected cycles of: d) C-framework and e) MoS2@CF sample under 40% compressive strain condition. Sequential photographs of MoS2@CF sample under: f) uniaxial compression and g) bending test. b-f) Reproduced with permission.[23] Copyright 2020, Elsevier. h) The electronic conductivity values of MoS2/C NSAs and MoS2 NSAs during the bending test for

1000 cycles, i) the charge/discharge curves of the assembled MoS2/C NSAs flexible battery under the flat state and after 1, 100, and 200 bending cycles, (j-l) a white LED connected to the flexible battery under the flat and bending states and after 200 bending cycles. h-l) Reproduced with permission[41]. Copyright 2017, Elsevier. m) Digital photographs of N-CNF at different bending angels; n) stress-strain curve of N-CNF from tensile test. m,n) Reproduced with permission[87]. Copyright 2016, Wiley-VCH. -

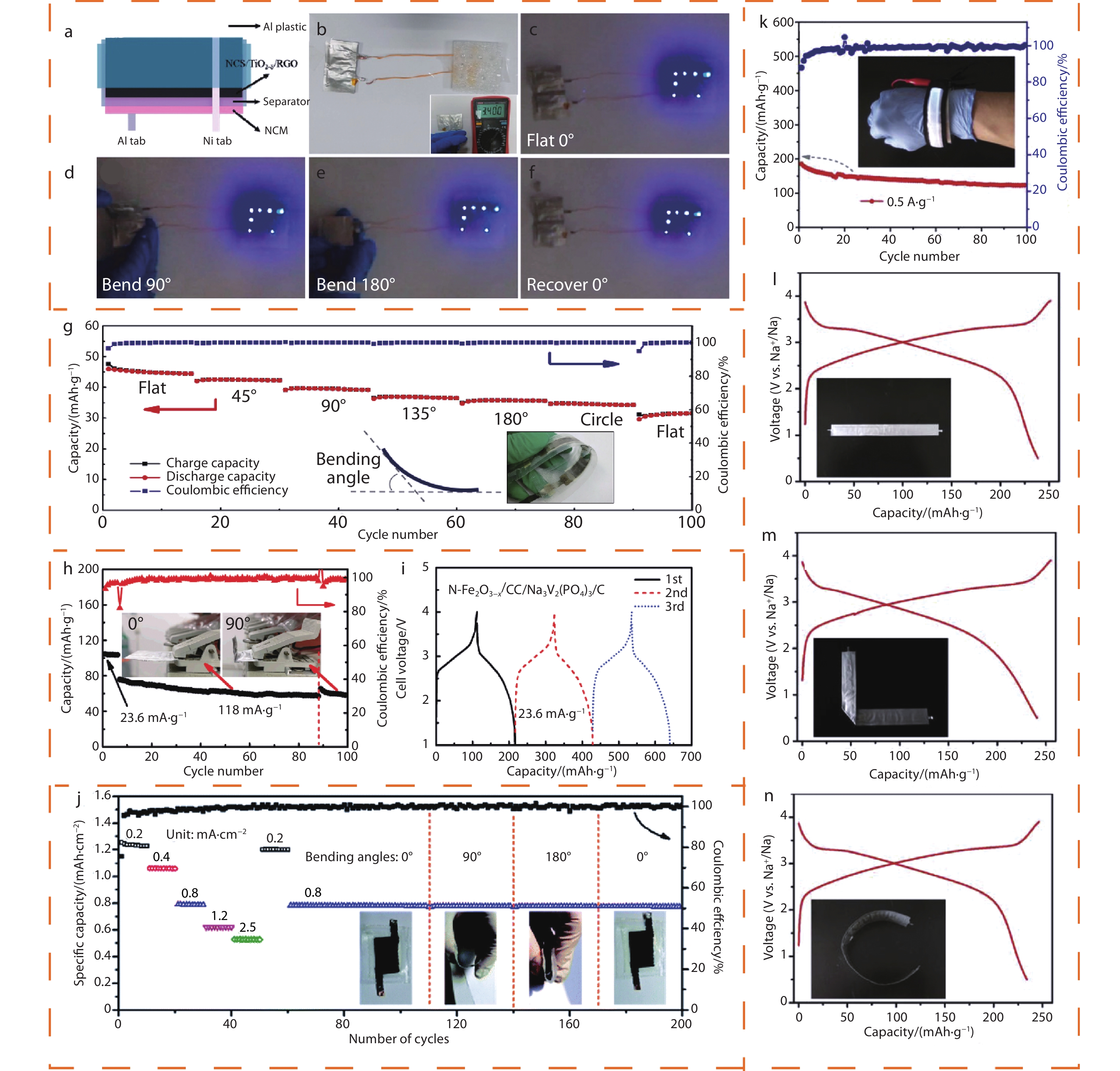

Figure 5.

(a) Schematic diagram of the soft-package NCS/TiO2-δ/RGO//NCM battery. (b) Photograph of the soft-package battery and “Li” model LEDs (the inset shows the open-circuit voltage). (c-f) The NCS/TiO2-δ/RGO//NCM battery was used to light “Li” model LEDs after bending at 0°, 90°, and 180° and recovering to 0°, respectively. a-f) Reproduced with permission[86]. Copyright 2019, American Chemical Society. g) Flexible Belt-Shaped Na0.44MnO2// NaTi2(PO4)3@C Battery: Cycling profile under different bending conditions tested at a current density of 0.2 A g−1. Inset is Photo profile of an as-prepared belt-shaped aqueous SIB. Reproduced with permission[124]. Copyright 2017, Elsevier. h) Galvanostatic profiles of full cell upon initial cycles. i) Cycle performance and bending test of full cell. h,i) Reproduced with permission[89]. Copyright 2020, Wiley-VCH. j) Rate performance and flexible test of CC-NVPO k PCC-TiO2 dot-16 full cell and inset shows the images of a soft-pack battery under different bending states[87]. Reproduced with permission[90]. Copyright 2019, Royal Society of Chemistry. k) of the flexible full battery; a flexible LED bracelet lighted by the prepared SIB full battery (inset). Galvanostatic charge/discharge profiles of the flexible battery under various shapes: flat state (j), 90° (m) and a cycle (n). k-n) Reproduced with permission[88]. Copyright 2018, Elsevier.

-

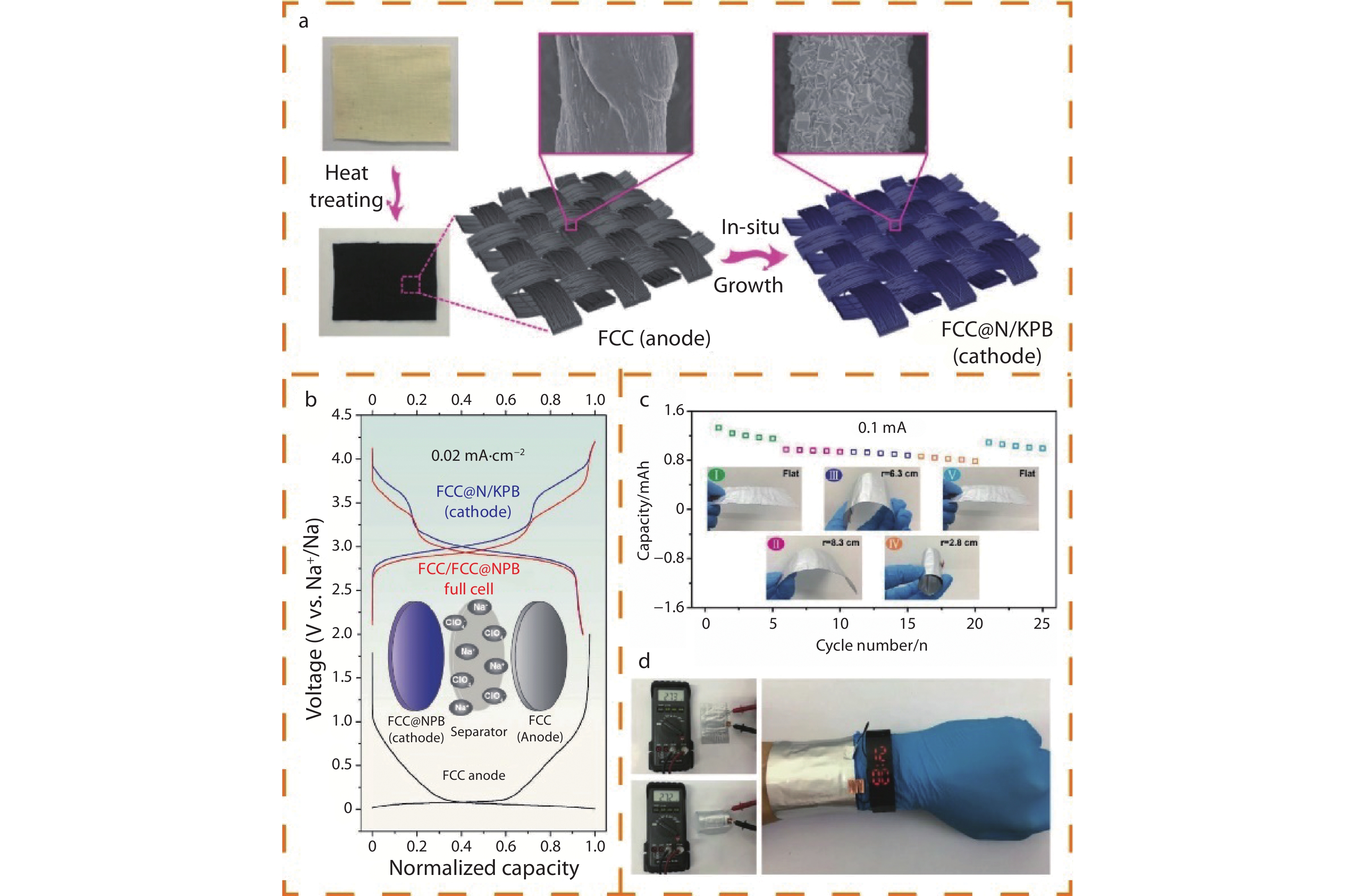

Figure 6.

a) The schematic illustration of the formation process for the flexible binder-free FCC anode and FCC@N/KPB cathode. b) The GCD curves of FCC anode, FCC@NPB cathode, and FCC//FCC@NPB full cell at a current density of 0.02 mA cm−2; c) Cycling stability of the FCC//FCC@NPB at different bending states (the inset shows the flexibility with different mandrel radius) at a current of 0.1 mA; d) Left: The voltage of FCC//FCC@NPB flexible pouch cell at the state of flat and bending; right: the application demonstration of commercial electronic watch by using the FCC//FCC@NPB flexible pouch cell as power supply[112]. a-d) Reproduced with permission.[112] Copyright 2019, Wiley-VCH.

-

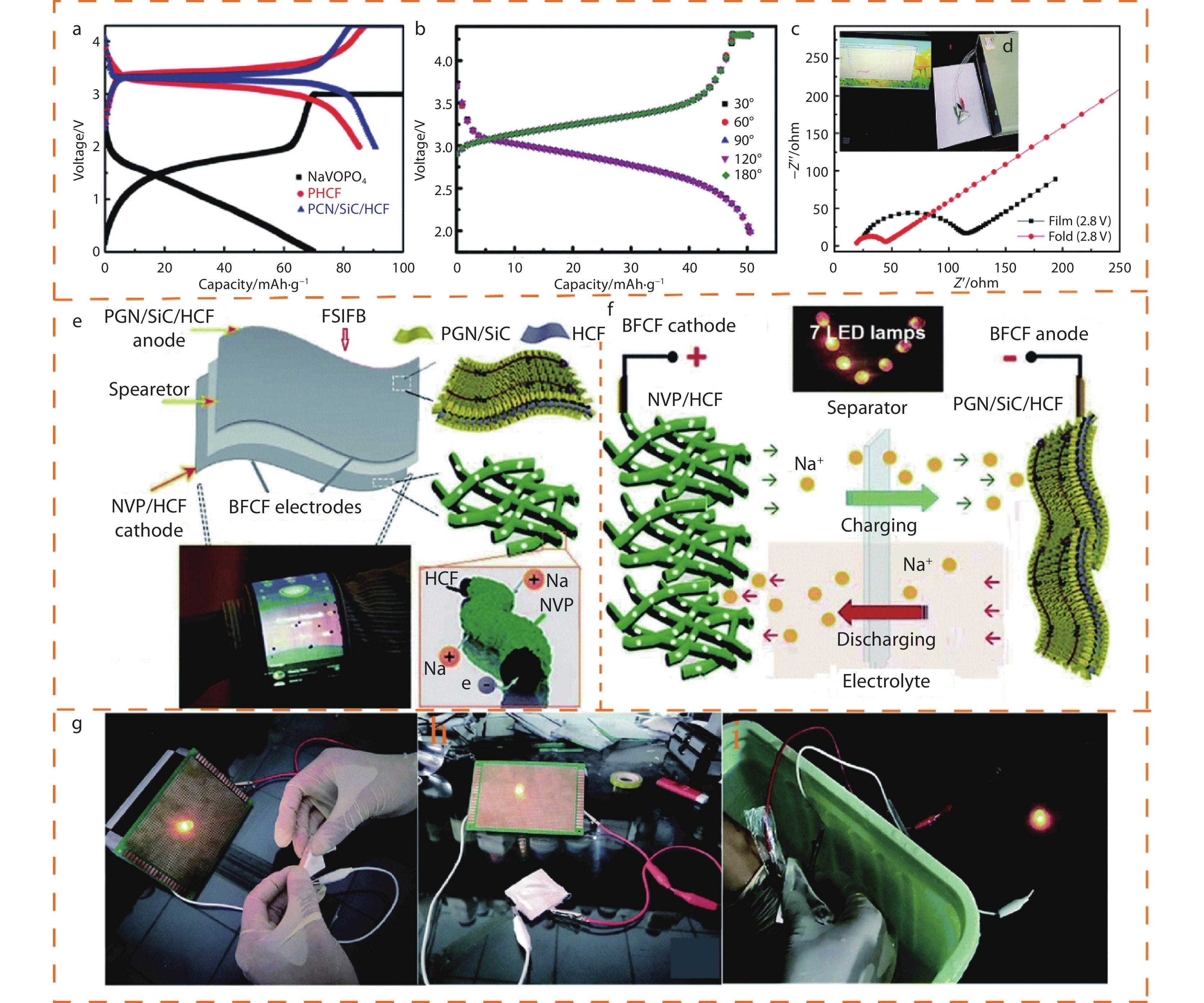

Figure 7.

a) Sodium storage performances of the pouch-type FSIFBs assembled with the BFCF-NVP/HCF cathode and the different anodes at different current rates of the cathode. b) Charge–discharge curves of the pouch-type FSIFB assembled with the BFCF-NVP/HCF cathode and the PGN/SiC/HCF anode at 5C after bending at different angles from 180 to 30. c) Nyquist plots of the FSIFB before and after being folded at a bending angle of 120 at 2C and 2.8 V. d) EIS test photograph of the bent pouch-type FSIFB. e) Schematic illustrations for the fabrication and microstructure of the flexible sodium-ion full battery (FSIFB) using the BFCF-NVP/HCF cathode and the PGN/SiC/HCF anode. f) Schematic diagram of the FSIFB. g) Bending and waterproofing tests on pouch type FSIFB. a-g) Reprinted with permission.[91] Copyright 2016, Royal Society of Chemistry.

-

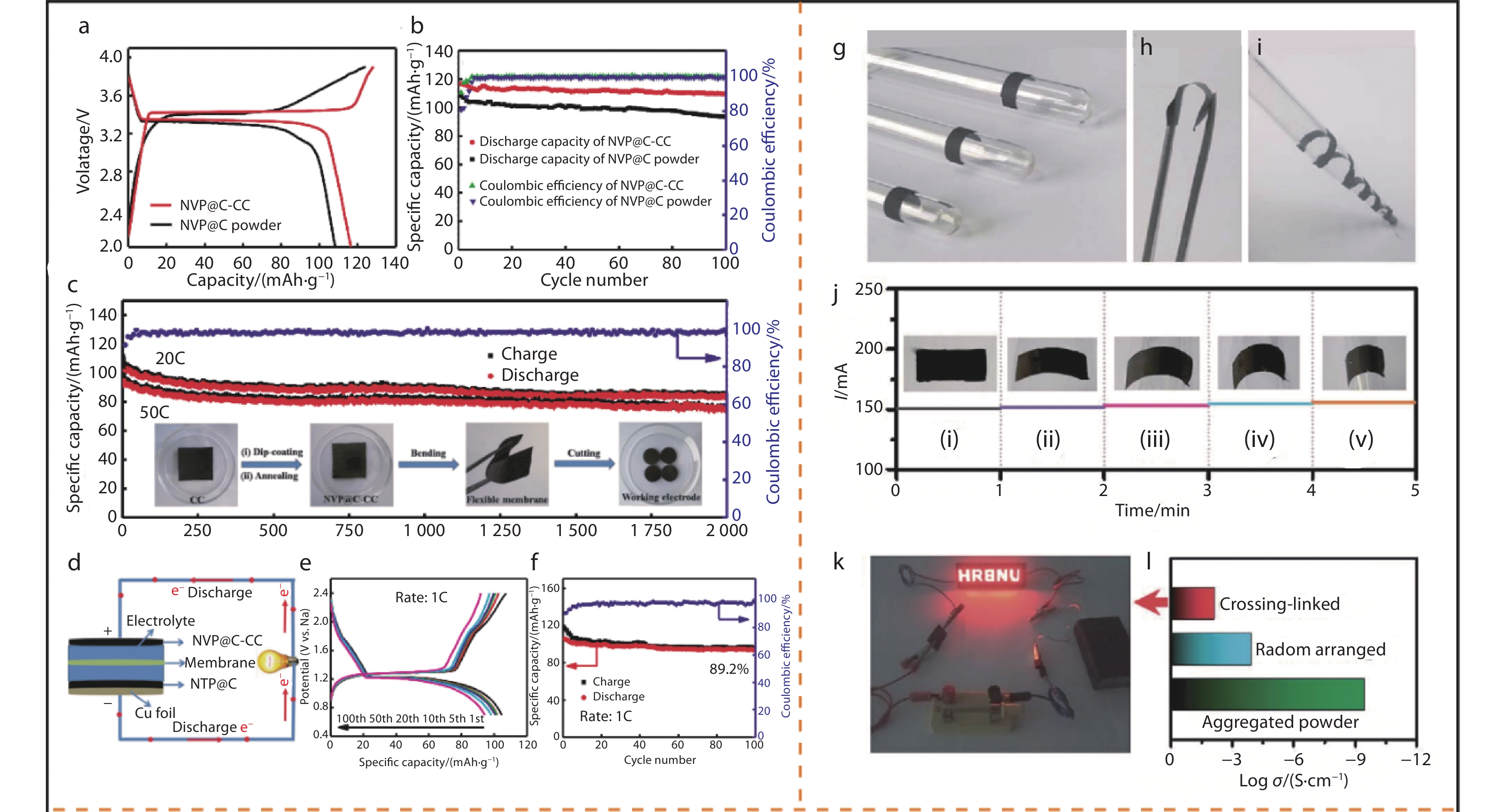

Figure 8.

(a) Voltage profiles of NVP@C-CC and NVP@C powder in the voltage range from 2 to 3.9 V vs. Na+/Na at 1 C. (b) Cycling performance of NVP@C-CC and NVP@C powder at 1 C. (c) The long-term cycling stability of NVP@C-CC at 20 and 50 C. The inset in (c) is NVP@C-CC film preparation process and flexibility demonstration. (d) Schematic (e) Voltage profiles and (f) Cycling performance of NVP@C-CC//NTP@C full cell in the voltage range from 0.7 to 2.4 V vs. Na+/Na at 1 C. a-f) Reprinted with permission.[113] Copyright 2018, Elsevier. (g–i) photographs and (j) current–time curves of the crosslinked nanofiber film bent with different curvatures. In (j), (i) to (v) represent five different bending states. (k) Application of the crosslinked nanofiber as a connection part in an electric circuit. g-k) Reprinted with permission[107]. Copyright 2019, Royal Society of Chemistry.

-

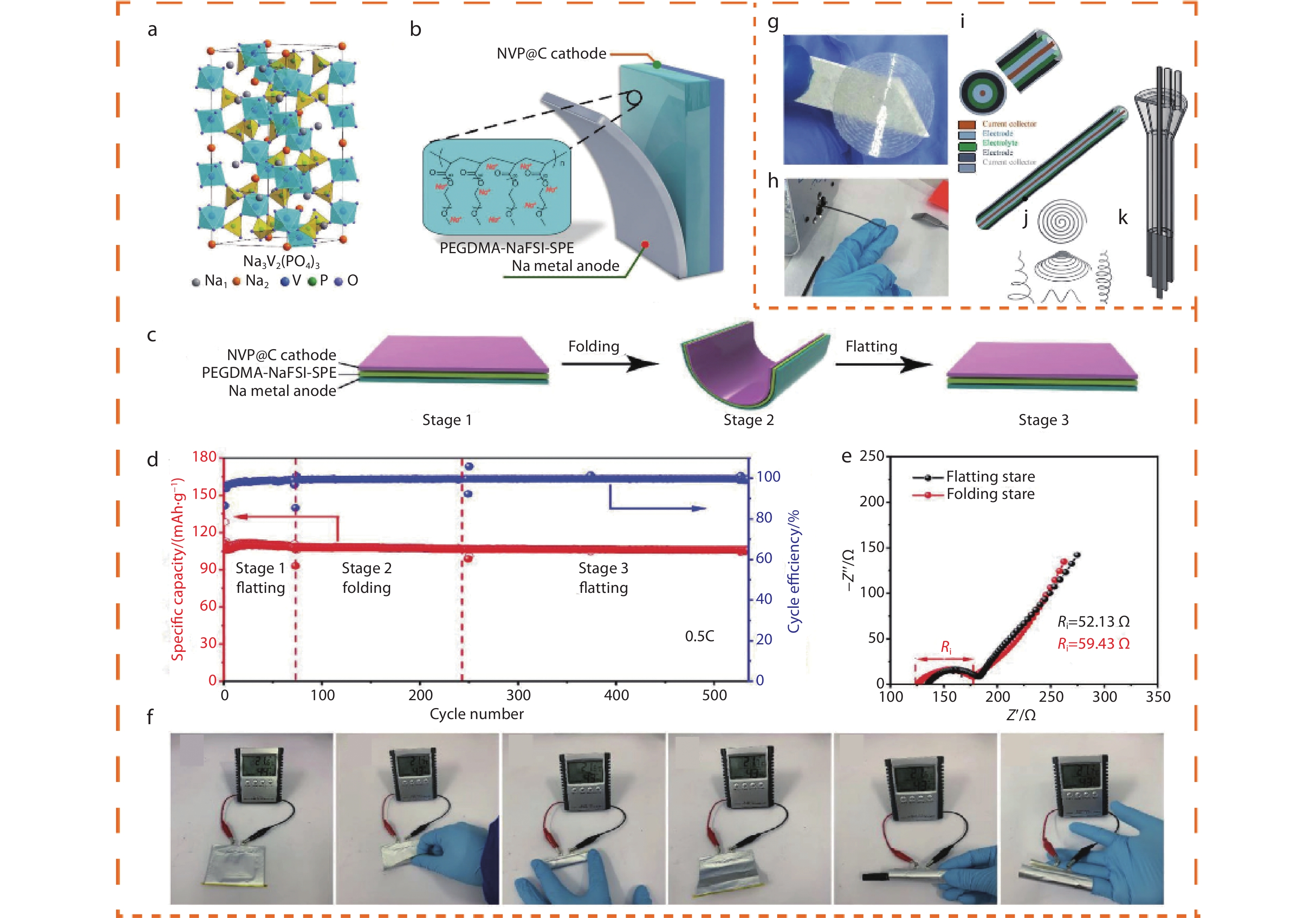

Figure 9.

a) Crystal structure of Na3V2(PO4)3 (NVP). b) The construction architecture of the NVP@C|PEGDMA-NaFSI-SPE|Na. c) Schematic of the bendable NVP@C|PEGDMA-NaFSI-SPE|Na ASSB. d) Cycling performance and corresponding Coulombic efficiency at 0.5 C. e) Nyquist plots in flatting or folding state. f) Flexibility and safety evaluation under different conditions of the bendable soft- pack battery. Optical images of the disc-shape printed solid electrolyte. a-f) Reproduced with permission[115]. Copyright 2018, Wiley-VCH. (g) and cathode filament extrusion (h) and schematic design of multi-coaxial battery (i), possible configurations of printed flexible multi-coaxial cable battery (j), cross-sectional view of the extrusion nozzle (k). g-k) Reproduced with permission[116]. Copyright 2020, Manchester Nh: Electrical Society.

-

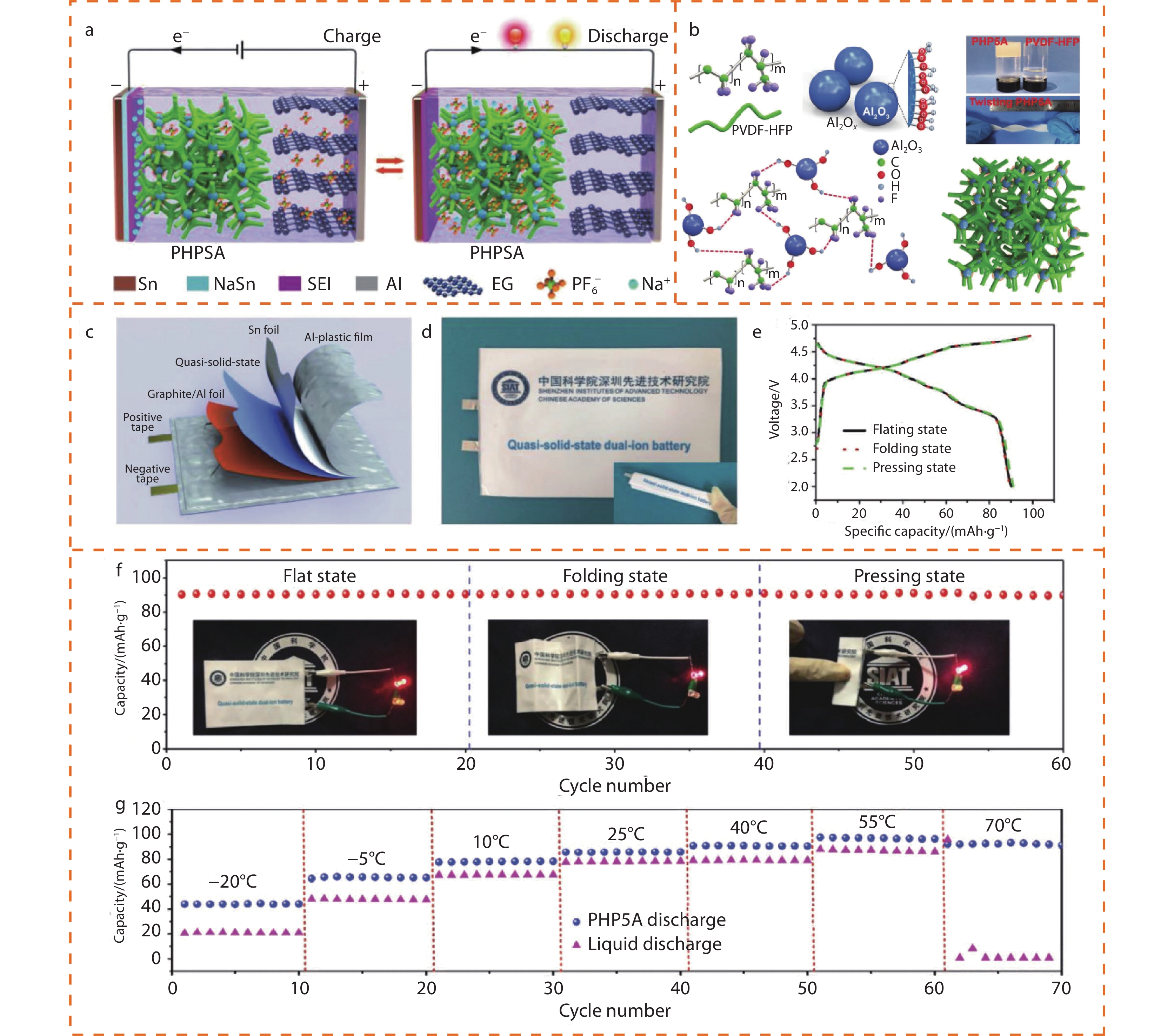

Figure 10.

a) Schematic illustration of the configuration and working mechanism of a QSS-SDIB wherein Na+ cations migrate to Sn foil anode to form NaSn alloy and PF6-anions intercalate into graphite cathode during the charging process. b): i) 3D diagram of PVDF-HFP chemical structure. ii) 3D diagram of Al2O3 nanoparticles with hydroxyl on the surface. iii) Typical images of the quasi-solid-state PHP5A after the addition of Al2O3 and the liquid state of PVDF-HFP without Al2O3. iv) Typical image of the quasi-solid-state electrolyte under severely twisting. v) Schematic diagram and vi) 3D schematic diagram of the quasi-solid-state polymer PHPA formed by Lewis acid–base intermolecular bonding between PVDF-HFP and Al2O3 nanoparticles. c) Schematic structure of the flexible QSS-SDIB. d) Optical photographs of the fabricated flexible QSS-SDIB and the inset is flexible QSS-SDIB in pressed state. e) Charge/discharge profile of flexible QSS-SDIB at the flat, folding, and pressing states. f) Cycling stability of flexible PHP5A-DIB and the insets are the optical photographs of the flexible DIBs under flat, folding, and pressing states, which can light up two LEDs (yellow and red) in series. g) Discharge capacities of the SDIBs based on PHP5A QSSE and liquid electrolyte at various temperatures. Reproduced with permission[117]. Copyright 2018, Wiley-VCH.

-

Figure 11.

Schematic of preparation steps of conductive PDMS/rGO sponge. a) While the PDMS/GO sponge (insulating) was brownish in color, once the material was reduced to rGO (conductive), the material appeared black. Schematic of preparation steps of conductive PDMS/rGO sponge. b) While the PDMS/GO sponge (insulating) was brownish in color, once the material was reduced to rGO (conductive), the material appeared black. c) Schematic illustration of the fabricated stretchable PDMS/rGO sponge/VOPO4//PDMS/rGO sponge/hard carbon sodium-ion full battery. d,e) Photographs of the stretchable sodium-ion full battery in the unstretched state (top) and stretched state with ≈50% strains (bottom) to power a commercial LED light. a-e) Reproduced with permission[120]. Copyright 2017, Wiley-VCH.

-

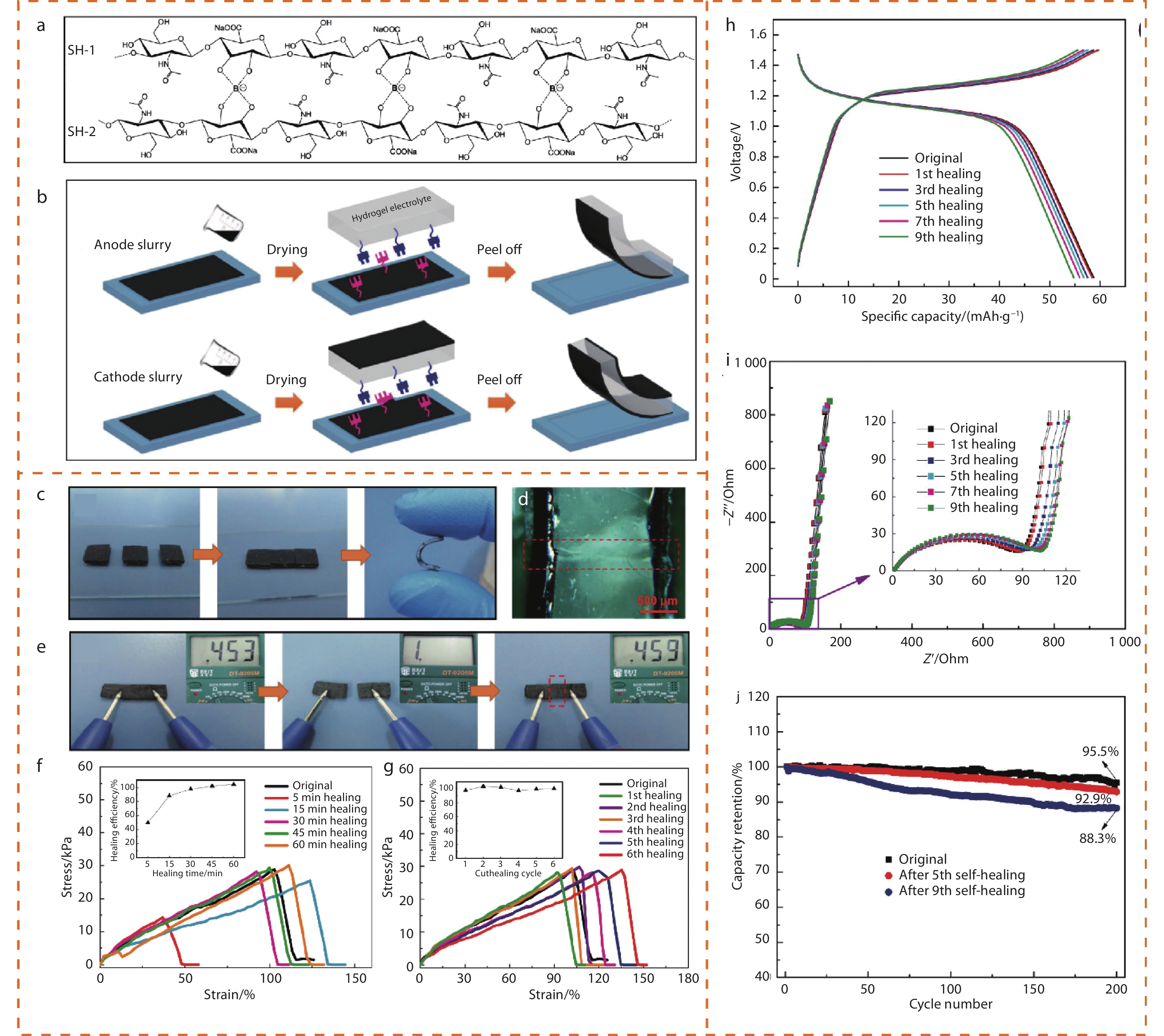

Figure 12.

Illustration of the (a) formation of dynamic borate ester bonding between SH chains and (b) fabrication of a self-healable SIB or asymmetric capacitor. The anode and cathode films are first prepared through a casting process and then successively coated onto the opposite sides of the SH/NaNO3 hydrogel electrolyte. (c) Self-healing of the SIB after cutoff under ambient conditions. (d) Cross-sectional image of the healed region observed by optical microscopy. (e) Resistance variation of the battery during the cut/healing process. Stress-strain curves of the battery (f) at different healing stages and (g) after multiple cut/healing cycles. The insets are the mechanical healing efficiency calculated from the corresponding stress-strain curves. The healing duration for each cycle was 60 min. Electrochemical performances of the SIB and the asymmetric capacitor before and after self-healing. GCD profiles of the (h) battery at 0.2 A g−1 and (i) Nyquist plots of the battery. Cycling characteristics of the (j) battery at 0.2 A g−1. Reproduced with permission.[110] Copyright 2019, American Chemical Society.

-

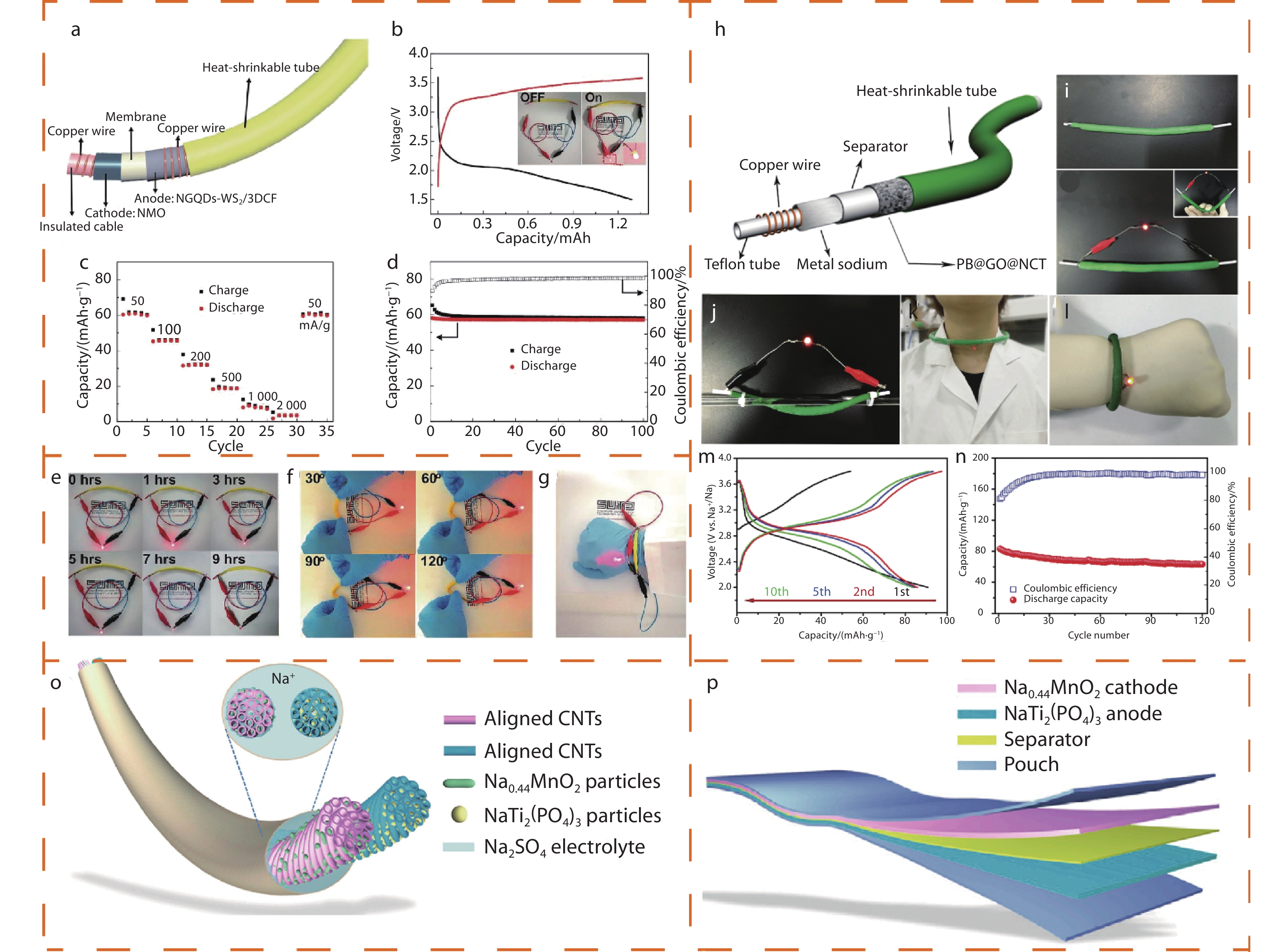

Figure 13.

Flexible cable-shaped SIB with NGQDs-WS2/3DCF as the anode electrode. (a) Schematic of the structure. (b) Galvanostatic charge and discharge curves at a current of 3 mA (third cycle after two pre-activation cycles). The inset is the cable-shaped SIB to power a red LED with off and on status. (c) Rate capability and (d) cycle stability and related coulombic efficiency at a current density of 50 mA g−1 of the cable-shaped SIBs. (e) A red LED powered by a 7 cm cable-shaped SIB for 9 hours. (f) Photographs of a red LED powered by the cable-shaped SIB at various bending angles. (g) Picture of the cable-shaped SIB as a wrist strap battery to power a red LED. a-g) Reproduced with permission[108]. Copyright 2018, Royal Society of Chemistry. h) Schematic illustration for the structure of the tube-type flexible SIBs. i) Digital photograph of the fabricated tube-type flexible SIBs.j–l) Demonstration of an LED lighting by tube-type flexible SIBs under different conditions. m) Charge–discharge profiles of tube-type flexible SIBs at a current density of 50 mA g−1. n) Cycles performance of tube-type flexible SIBs at a current density of 100 mA g−1. h-n) Reproduced with permission.[111] Copyright 2017, Wiley-VCH. o) the Flexible Belt-Shaped and p) Flexible Fiber-Shaped Na0.44MnO2//NaTi2(PO4)3@C Battery Using 1 M Na2SO4 as Electrolyte. o, p) Reproduced with permission[124]. Copyright 2017, Elsevier.

-

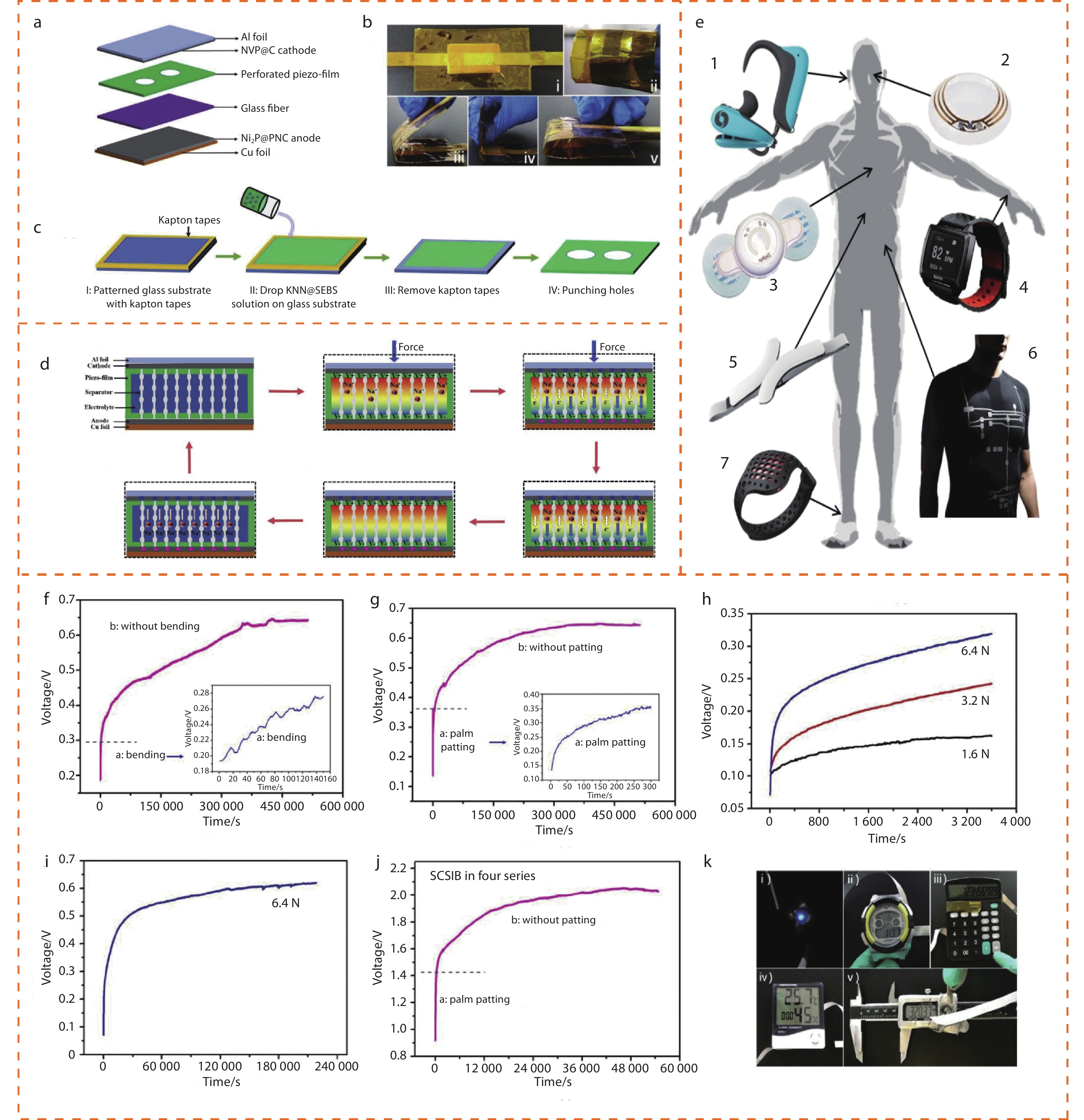

Figure 14.

(a) Device architecture of the flexible SCSIB. (b) SCSIB demonstrates excellent flexibility: i) optical image of a flexible SCSIB, ii) SCSIB can be rolled in a circle, iii-v) SCSIB can be bent with various angles (0, 45°, and 90°), (c) Synthetic procedure of the perforated elastic KNN@SEBS piezo-film for the flexible SCSIB, (d) Schematic illustration of the self-charging mechanism of the flexible SCSIB. (e) Various wearable devices based on the human body in the future. Self-charging behaviors of the flexible SCSIB: (f) Self-charging process of a single device treated by bending (the inset is the enlarged charging curve at the initial 150 s), (g) Self-charging process of a single device treated by palm patting (the inset is the enlarged charging curve at the initial 300 s), (h) Self-charging curve of a single device treated by loading at 1.6, 3.2 and 6.4 N in

3600 s, (i) Self-charging curve of a single device applied at 6.4 N with long-time, (j) Self-charging curve of four serially connected flexible devices treated by palm patting and (k) some display applications (i-iv): the serially connected devices can power a LED light, a smartwatch, an electric calculator, a humidity indicator, and a digital Vernier calliper. a-d, f-k) Reproduced with permission[125]. Copyright 2019, Elsevier. -

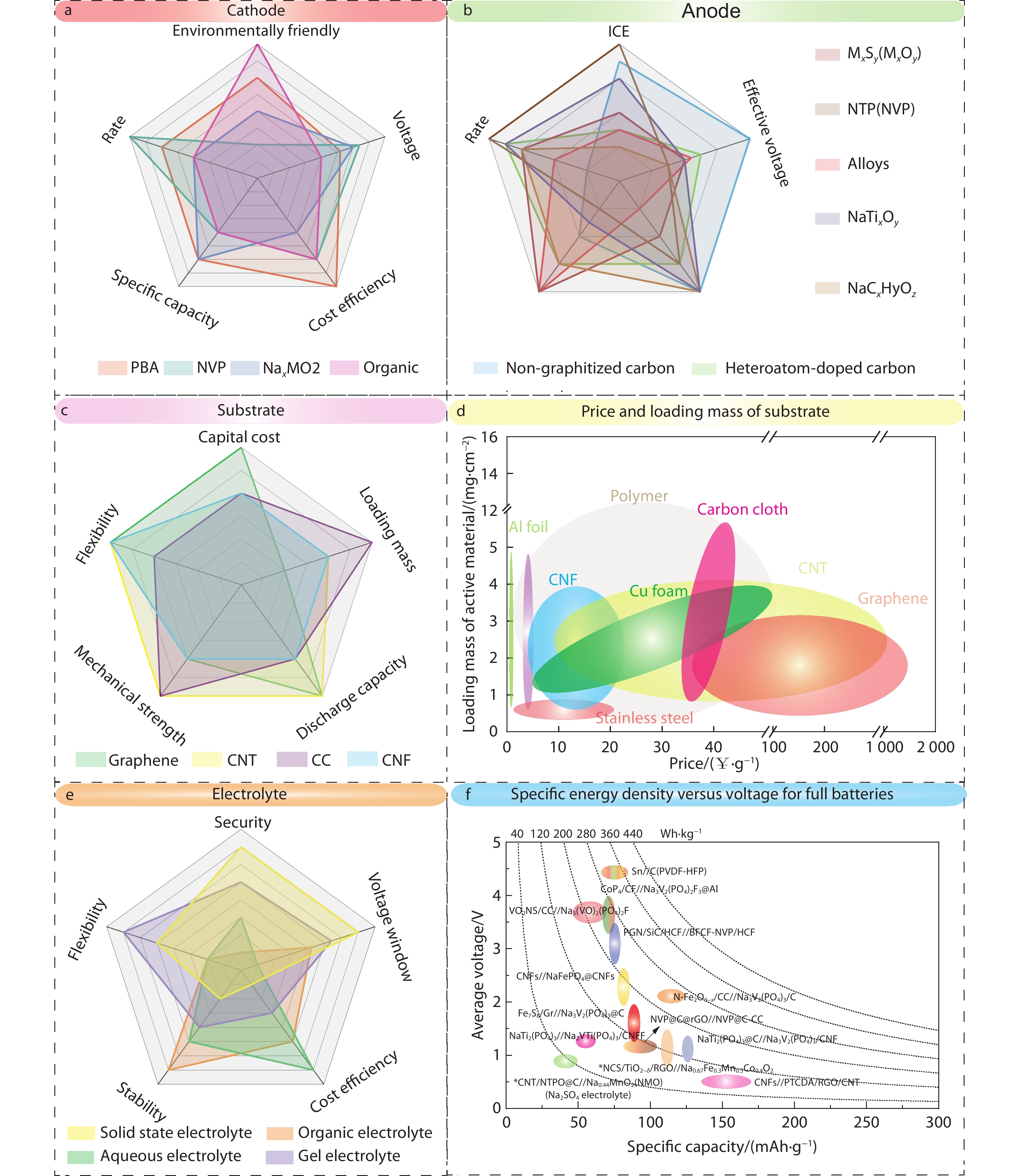

Figure 15.

Comparison of various performance indicators of a) Cathode; b) Anode; c) Substrate; e) Electrolyte. d) Comparison of loading mass and price for different substrates. f) Comparison of full cell specific energy density with different cathode and anode material matching.

Xiang-Xi He is received his M.S. degree from School of Environmental and Chemical Engineering, Shanghai University in 2021. Currently he is a doctoral candidate in the School of Environmental and Chemical Engineering, Shanghai University. His research focuses on the structural design, mechanistic investigation and commercialization of advanced carbon anode materials for alkali metal batteries.

Xiang-Xi He is received his M.S. degree from School of Environmental and Chemical Engineering, Shanghai University in 2021. Currently he is a doctoral candidate in the School of Environmental and Chemical Engineering, Shanghai University. His research focuses on the structural design, mechanistic investigation and commercialization of advanced carbon anode materials for alkali metal batteries.  Li Li now works at Shanghai University. She obtained her Ph.D. degree from the University of Wollongong in 2014. Her research interests are mainly focused on the fabrication of materials and their application in rechargeable batteries, including lithium-ion batteries, sodium-ion batteries, and potassium-ion batteries.

Li Li now works at Shanghai University. She obtained her Ph.D. degree from the University of Wollongong in 2014. Her research interests are mainly focused on the fabrication of materials and their application in rechargeable batteries, including lithium-ion batteries, sodium-ion batteries, and potassium-ion batteries.  Shu-Lei Chou is a distinguished professor at the Institute of Carbon Neutralization, Wenzhou University. He obtained his Bachelor’s degree (1999) and Master’s degree (2004) from the Nankai University, China. He received his Ph.D. degree from the University of Wollongong in 2010. His research interests include energy storage materials for battery applications, especially novel composite materials, new binders, and new electrolytes for Li/Na batteries.

Shu-Lei Chou is a distinguished professor at the Institute of Carbon Neutralization, Wenzhou University. He obtained his Bachelor’s degree (1999) and Master’s degree (2004) from the Nankai University, China. He received his Ph.D. degree from the University of Wollongong in 2010. His research interests include energy storage materials for battery applications, especially novel composite materials, new binders, and new electrolytes for Li/Na batteries.

DownLoad:

DownLoad: