| Citation: | Chaofeng Wu, Wen Gong, Jinfeng Geng, Jianye Cui, Lipeng Mi, Zhixiang Zhu, Jingkai Nie, Qiang He, Zhongshang Dou, Xuting Qiu, Fang-Zhou Yao, Ke Wang. Additive manufacturing: pushing the boundaries of piezoelectric materials[J]. Materials Lab, 2023, 2(2): 230002. doi: 10.54227/mlab.20230002 |

Additive manufacturing: pushing the boundaries of piezoelectric materials

-

Abstract

Piezoelectric effects have attracted long-term research both from academic and industrial interests. However, constrained by their inherent crystal symmetry, conventional piezoelectric materials have limited non-zero piezoelectric coefficients, which impedes the practical applications thereof. Inspired by metamaterial design, artificial anisotropy was proposed to achieve all non-zero piezoelectric coefficients. Here, the design concepts and preparation methods of piezoelectric metamaterials were surveyed. Although the realization of a full set of piezoelectric coefficients is inseparable from the construction of unique structure, compared with traditional approaches, additive manufacturing has appealing advantages in the complex, diverse and integrated process. It is believed that additive manufacturing holds infinite potential for manufacturing piezoelectric materials to break through their boundaries in the future.

-

-

References

1. P. A. Ersman, J. Eriksson, D. Jakonis, S. Pantzare, J. Åhlin, J. Strandberg, S. Sundin, H. Toss, F. Ahrentorp, K. Daoud, C. Jonasson, H. Svensson, G. Gregard, U. Näslund, C. Johansson, Adv. Eng. Mater., 2022, 24, 2200399 2. Z. Dong, P. Zhao, Z. Cen, X. Wang, J Am. Ceram. Soc., 2023, 106, 2953 3. H. Liu, Y. X. Liu, A. Song, Q. Li, Y. Yin, F. Z. Yao, K. Wang, W. Gong, B. P. Zhang, J. F. Li, Natl. Sci. Rev., 2022, 9, nwac101 4. X. Liu, P. Tan, X. Ma, D. Wang, X. Jin, Y. Liu, B. Xu, L. Qiao, C. Qiu, B. Wang, W. Zhao, C. Wei, K. Song, H. Guo, X. Li, S. Li, X. Wei, L. Q. Chen, Z. Xu, F. Li, H. Tian, S. Zhang, Science, 2022, 376, 371 5. Y. Zhang, Y. Yu, N. Zhang, T. Zheng, J. Wu, Adv. Funct. Mater., 2023, 23, 2211439 6. K. Roleder, I. Franke, A. M. Glazer, P. A. Thomas, S. Miga, J. Suchanicz, J. Phys.: Condens. Matter, 2002, 14, 5399 7. J. Wu, Z. Hu, X. Gao, M. Cheng, X. Zhao, W. Su, L. Wang, M. Guan, Y. Du, R. Mao, Z. Wang, Z. Zhou, S. Dong, M. Liu, J. Materiomics, 2021, 7, 254 8. W. Zhou, P. Chen, Q. Pan, X. Zhang and B. Chu, Adv. Mater., 2015, 27, 6349 9. J. Yang, Z. Li, X. Xin, X. Gao, X. Yuan, Z. Wang, Z. Yu, X. Wang, J. Zhou, S. Dong, Sci. Adv., 2019, 5, eaax1782 10. Z. Li, X. Yi, J. Yang, L. Bian, Z. Yu, S. Dong, Adv. Mater., 2022, 34, 2107236 11. J. Liu, X. Gao, H. Jin, K. Ren, J. Guo, L. Qiao, C. Qiu, W. Chen, Y. He, S. Dong, Z. Xu, F. Li, Nat. Commun., 2022, 13, 6567 12. C. Chen, X. Wang, Y. Wang, D. Yang, F. Yao, W. Zhang, B. Wang, G. A. Sewvandi, D. Yang, D. Hu, Adv. Funct. Mater., 2020, 30, 2005141 13. M. Rafiee, F. Granier, R. Tao, A. Bhérer-Constant, G. Chenier, D. Therriault, Adv. Eng. Mater., 2022, 24, 2200294 14. C. Zhang, Y. Li, W. Kang, X. Liu, Q. Wang, SusMat, 2021, 1, 127 15. Z. Chen, Z. Li, J. Li, C. Liu, C. Lao, Y. Fu, C. Liu, Y. Li, P. Wang, Y. He, J. Eur. Ceram. Soc., 2019, 39, 661 16. E. Cesewski, A. P. Haring, Y. Tong, M. Singh, R. Thakur, S. Laheri, K. A. Read, M. D. Powell, K. J. Oestreich, B. N. Johnson, Lab Chip, 2018, 18, 2087 17. S. Liu, W. Wang, W. Xu, L. Liu, W. Zhang, K. Song, X. Chen, Research, 2022, 2022, 9790307 18. K. Liu, C. Zhou, J. Hu, S. Zhang, Q. Zhang, C. Sun, Y. Shi, H. Sun, C. Yin, Y. Zhang, Y. Fu, J. Eur. Ceram. Soc., 2021, 41, 5909 19. K. Mondal, P. K. Tripathy, Materials, 2021, 14, 6442 20. H. Cui, R. Hensleigh, D. Yao, D. Maurya, P. Kumar, M. G. Kang, S. Priya, X. R. Zheng, Nat. Mater., 2019, 18, 234 21. D. Zhang, W. Jonhson, T. S. Herng, Y. Q. Ang, L. Yang, S. C. Tan, E. Peng, H. He, J. Ding, Mater. Horiz., 2020, 7, 1083 22. H. Cui, D. Yao, R. Hensleigh, H. Lu, A. Calderon, Z. Xu, S. Davaria, Z. Wang, P. Mercier, P. Tarazaga, X. R. Zheng, Science, 2022, 376, 1287 -

Rights and permissions

This is an open access article under the terms of the Creative Commons Attribution License, which permits use, distribution and reproduction in any medium, provided the original work is properly cited.

Information

Article Metrics

-

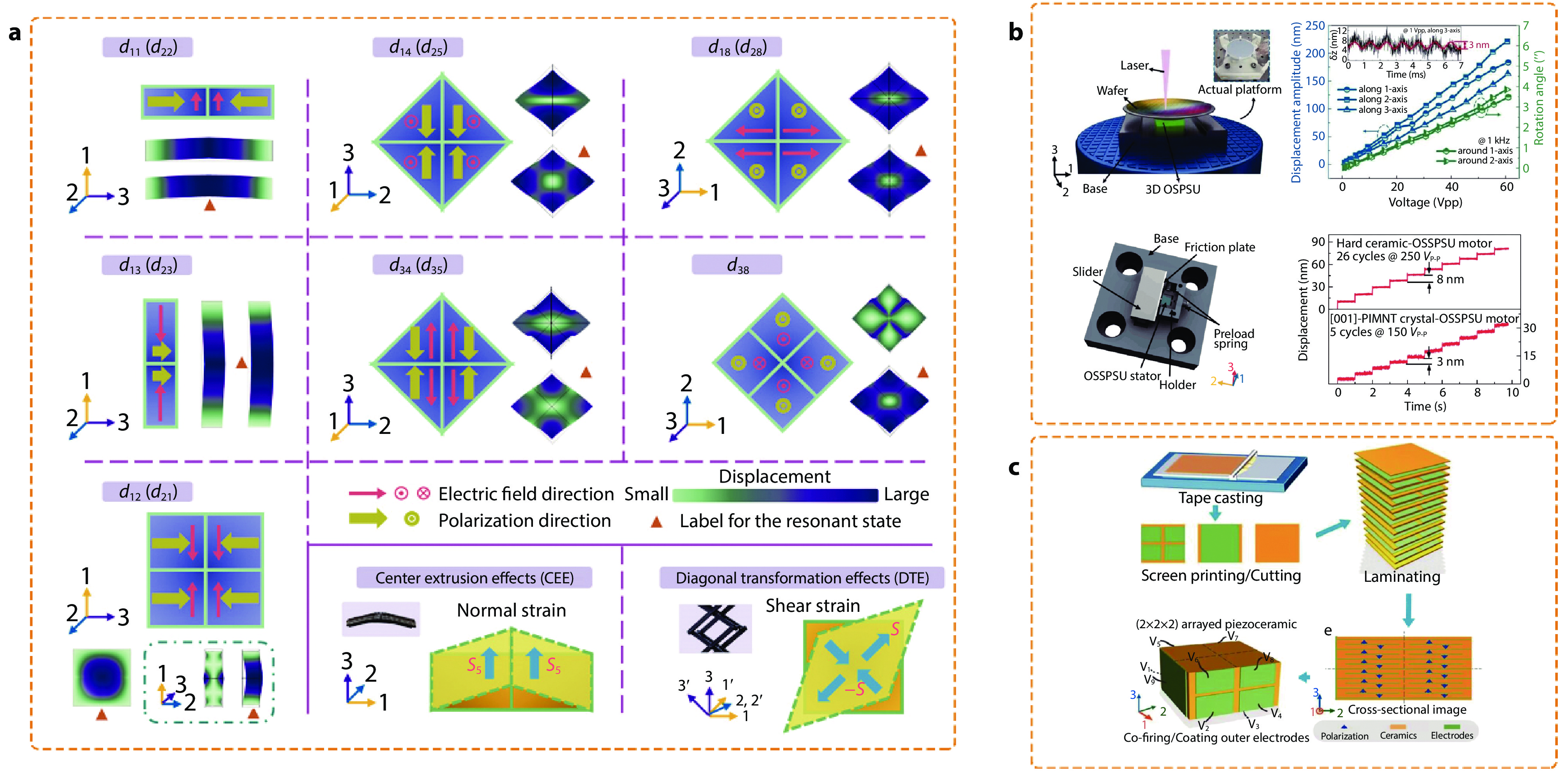

Figure 1.

a The schematic diagram of piezoelectric metamaterials prepared by traditional methods.[9] Copyright 2019, American Association for the Advancement of Science. b The design picture of a five-degree-of-freedom micro-nano operating platform with 3D OSPSU structure, and the driving displacement and rotation measured in each degree of freedom.[10] Copyright 2022, Wiley-Blackwell; the design of linear ultrasonic OSSPSU motor, and the step displacements of OSPSU motors made of [001]-PIMNT crystal and hard ceramics as a function of the cycle of pulse signals.[11] Copyright 2022, Springer Nature. c The traditional preparation processes of the (2 × 2 × 2) arrayed, co-fired 12-layer OSPSU: tape casting, screen printing and cutting, laminating, co-firing and coating external electrodes.[10] Copyright 2022, Wiley-Blackwell.

-

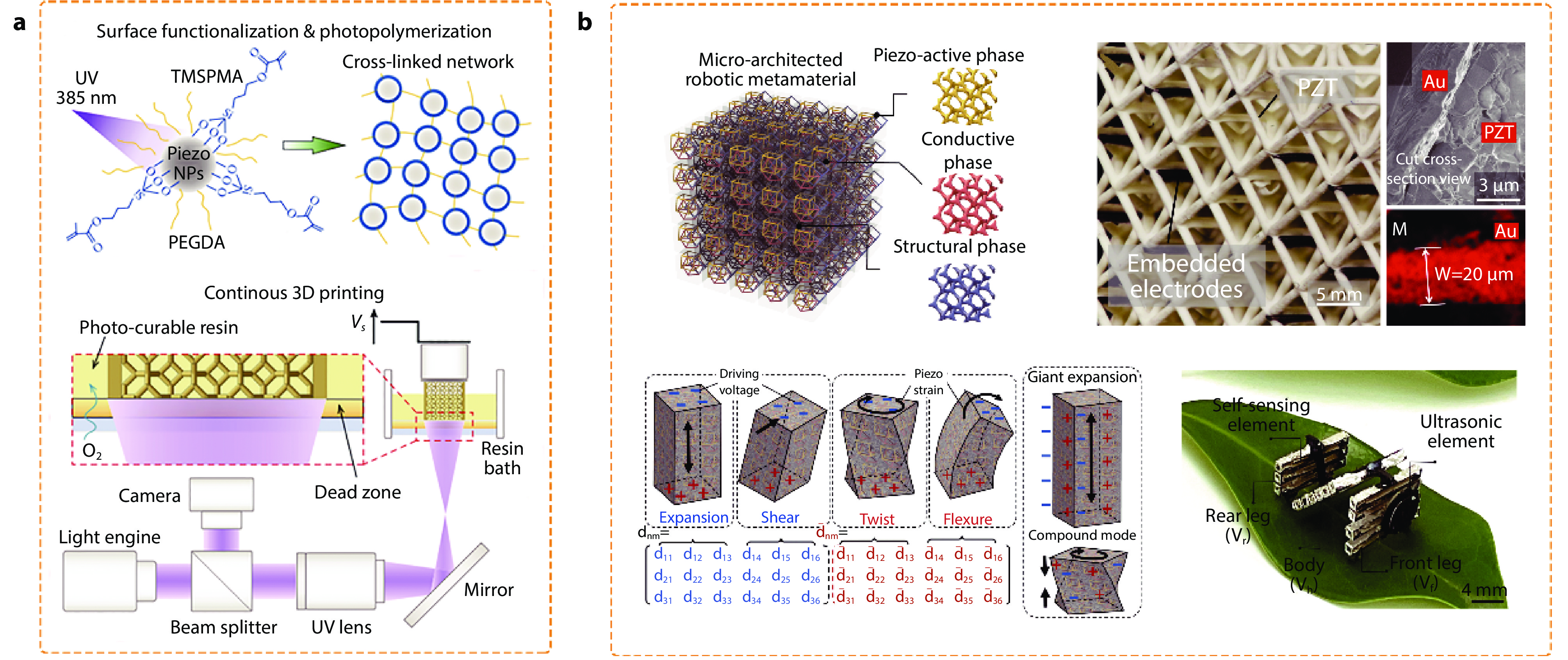

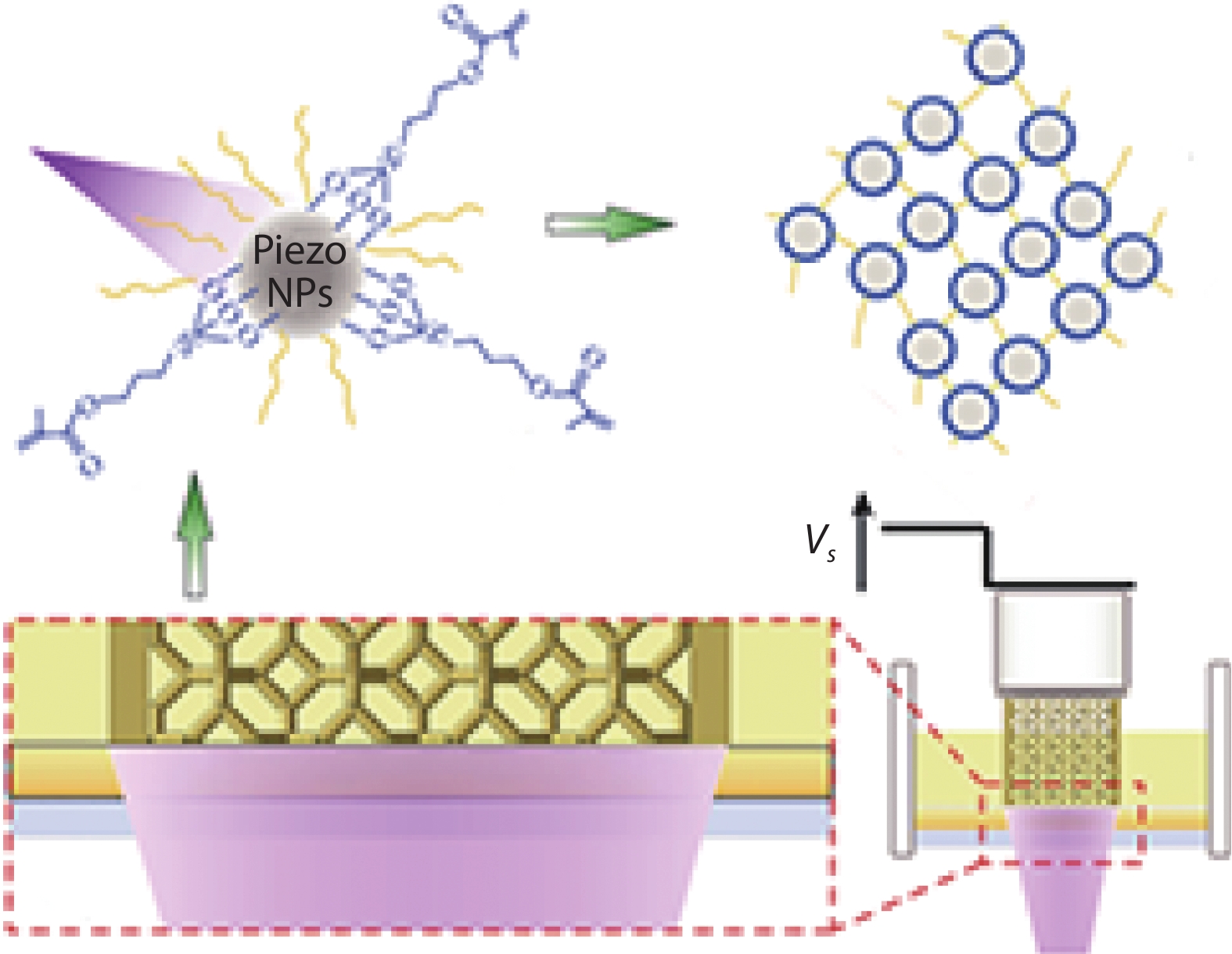

Figure 2.

a Schematic diagram of rapid and continuous 3D printing of piezoelectric sensors: basic principle and equipment.[17] Copyright 2022, American Association for the Advancement of Science. b The basic piezoelectric metamaterial: a 3D network consisted of piezoelectric, conductive and structural phases; 18 tensors in piezoelectric ceramics (blue), various strain modes realized by design of metamaterials and piezoelectric strain matrix with extended tensors (red); the images of piezoelectric metamaterials embedded in electrodes, including SEM images of PZT and Au electrodes boundaries and element diagrams of selectively deposited thin lines; the image of the mobile robot.[22] Copyright 2022, American Association for the Advancement of Science.

Chao-Feng Wu is currently the secretary general of the Advanced Ceramics and Devices Research Center, Yangtze Delta Region Institute of Tsinghua University, Zhejiang. He received his Ph.D. degree in materials science and engineering from Tsinghua University in 2018. His researches focus on high-performance lead-free ceramic materials and devices.

Chao-Feng Wu is currently the secretary general of the Advanced Ceramics and Devices Research Center, Yangtze Delta Region Institute of Tsinghua University, Zhejiang. He received his Ph.D. degree in materials science and engineering from Tsinghua University in 2018. His researches focus on high-performance lead-free ceramic materials and devices.  Xuting Qiu joined Research Center for Advanced Functional Ceramics of Wuzhen Laboratory in 2021. He received his Master degree from University of Chinese Academy of Sciences in 2020. His research interests focus on additive manufacturing of ceramics.

Xuting Qiu joined Research Center for Advanced Functional Ceramics of Wuzhen Laboratory in 2021. He received his Master degree from University of Chinese Academy of Sciences in 2020. His research interests focus on additive manufacturing of ceramics.  Fang-Zhou Yao is an associate professor at Wuzhen Laboratory. He received his Ph.D. degree from Tsinghua University in 2016. His primary research interests include high-performance lead-free piezoelectric materials and dielectric ceramics for electrostatic energy storage.

Fang-Zhou Yao is an associate professor at Wuzhen Laboratory. He received his Ph.D. degree from Tsinghua University in 2016. His primary research interests include high-performance lead-free piezoelectric materials and dielectric ceramics for electrostatic energy storage.  Ke Wang is a professor in the School of Materials Science and Engineering at Tsinghua University. He obtained his doctorate degree from Tsinghua University in 2010. He has devoted his career to the research of high-performance and environmentally friendly piezoelectric ceramic materials and devices.

Ke Wang is a professor in the School of Materials Science and Engineering at Tsinghua University. He obtained his doctorate degree from Tsinghua University in 2010. He has devoted his career to the research of high-performance and environmentally friendly piezoelectric ceramic materials and devices.

DownLoad:

DownLoad: