| Citation: | Qing Wang, Shufang Wang, Zhiliang Li. Low-dimensionalization enhancing the thermoelectric performance of higher manganese silicide[J]. Materials Lab, 2023, 2(2): 230013. doi: 10.54227/mlab.20230013 |

Low-dimensionalization enhancing the thermoelectric performance of higher manganese silicide

-

Abstract

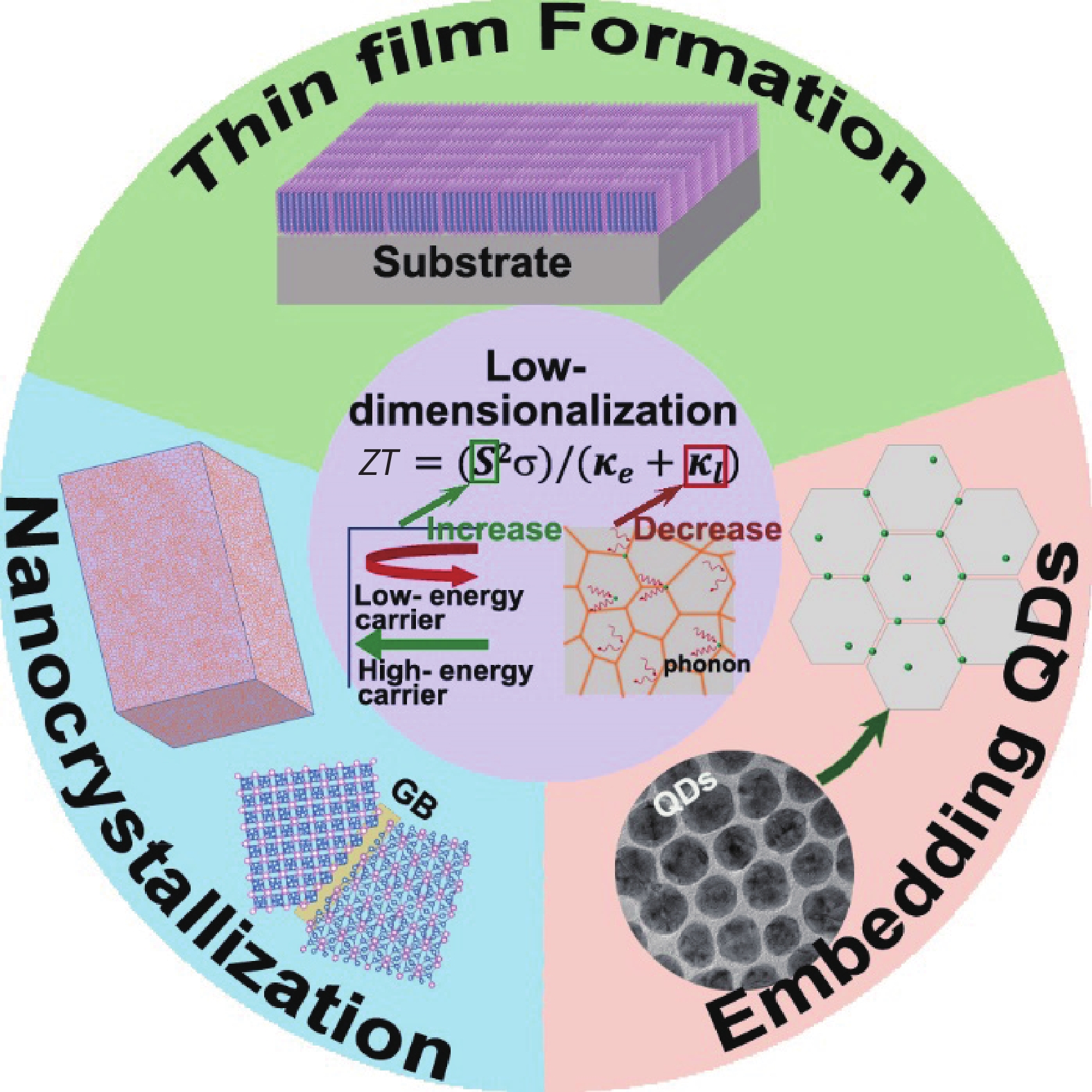

Higher manganese silicide (HMS) is a candidate thermoelectric (TE) material at medium temperature due to its non-toxicity, abundance, and competitive price. The focus on improving the TE performance of HMS is to decrease the thermal conductivity. Low-dimensionalization techniques, such as nanocrystallization, embedding quantum dots (QDs) and thin film formation are effective strategies to decrease the lattice thermal conductivity by enhancing the phonon scattering on interfaces. Additionally, the Seebeck coefficients also can be improved due to the energy filtering effect via the interface barrier, and correspondingly increasing the power factor of HMS. The TE performance of HMS can be enhanced due to synergistically optimized electrical and thermal properties.

-

-

References

1. M. Li, M. Hong, M. Dargusch, J. Zou, Z.-G. Chen, Trends Chem., 2021, 3, 561 2. W. P. Q. Ng, H. L. Lam, P. S. Varbanov, J. J. Klemeš, Energy Convers. Manag., 2014, 85, 866 3. K. F. Hsu, S. Loo, F. Guo, W. Chen, J. S. Dyck, C. Uher, T. Hogan, E. K. Polychroniadis, M. G. Kanatzidis, Science, 2004, 303, 818 4. G. J. Snyder, E. S. Toberer, Nat. Mater., 2008, 7, 105 5. L. E. Bell, Science, 2008, 321, 1457 6. J. He, T. M. Tritt, Science, 2017, 357, eaak9997 7. J. P. Heremans, V. Jovovic, E. S. Toberer, A. Saramat, K. Kurosaki, A. Charoenphakdee, S. Yamanaka, G. J. Snyder, Science, 2008, 321, 554 8. L. Su, D. Wang, S. Wang, B. Qin, Y. Wang, Y. Qin, Y. Jin, C. Chang, L.-D. Zhao, Science, 2022, 375, 1385 9. A. Zevalkink, D. M. Smiadak, J. L. Blackburn, A. J. Ferguson, M. L. Chabinyc, O. Delaire, J. Wang, K. Kovnir, J. Martin, L. T. Schelhas, T. D. Sparks, S. D. Kang, M. T. Dylla, G. J. Snyder, B. R. Ortiz, E. S. Toberer, Appl. Phys. Rev., 2018, 5, 021303 10. L. D. Ivanova, Inorg. Mater., 2011, 47, 965 11. L.-D. Zhao, S.-H. Lo, Y. Zhang, H. Sun, G. Tan, C. Uher, C. Wolverton, V. P. Dravid, M. G. Kanatzidis, Nature, 2014, 508, 373 12. A. A. Olvera, N. A. Moroz, P. Sahoo, P. Ren, T. P. Bailey, A. A. Page, C. Uher, P. F. P. Poudeu, Energy Environ. Sci., 2017, 10, 1668 13. D.-K. Shin, S.-W. You, I.-H. Kim, J. Korean Phys. Soc., 2014, 64, 1412 14. M. Saleemi, A. Famengo, S. Fiameni, S. Boldrini, S. Battiston, M. Johnsson, M. Muhammed, M. S. Toprak, J. Alloys Compd., 2015, 619, 31 15. P. Norouzzadeh, Z. Zamanipour, J. S. Krasinski, D. Vashaee, J. Appl. Phys., 2012, 112, 124308 16. D. Y. N. Truong, H. Kleinke, F. Gascoin, Intermetallics, 2015, 66, 127 17. W.-D. Liu, Z.-G. Chen, J. Zou, Adv. Energy Mater., 2018, 8, 1800056 18. Q. Wang, S. Song, X. Yang, Z. Liu, Y. Ma, X. San, J. Wang, D. Zhang, S. Wang, Z. Li, J. Materiomics, 2021, 7, 377 19. Z. Li, J.-F. Dong, F.-H. Sun, S. Hirono, J.-F. Li, Chem. Mater., 2017, 29, 7378 20. Z. Li, J.-F. Dong, F.-H. Sun, Asfandiyar, Y. Pan, S.-F. Wang, Q. Wang, D. Zhang, L. Zhao, J.-F. Li, Adv. Sci., 2018, 5, 1800626 21. Q. Zhang, X. Ai, L. Wang, Y. Chang, W. Luo, W. Jiang, L. Chen, Adv. Funct. Mater., 2015, 25, 966 22. Q. Wang, Z. Li, X. Yang, X. Qian, L. Guo, J. Wang, D. Zhang, S.-F. Wang, J. Mater. Sci. Technol., 2022, 111, 279 23. X. Chen, Z. Zhou, Y. Lin, C. Nan, J. Materiomics, 2020, 6, 494 24. Y. Okamoto, J. Saeki, T. Ohtsuki, H. Takiguchi, Appl. Phys. Express, 2008, 1, 117001 25. H.-C. Chien, C.-R. Yang, L.-L. Liao, C.-K. Liu, M.-J. Dai, R.-M. Tain, D.-J. Yao, Appl. Therm. Eng., 2013, 51, 75 26. H. Ohta, S. Kim, Y. Mune, T. Mizoguchi, K. Nomura, S. Ohta, T. Nomura, Y, Nakanishi, Y, Ikuhara, M, Hirano, H. Hosono, K. Koumoto, Nat. Mater., 2007, 6, 129 27. H. Böttner, G. Chen, R. Venkatasubramanian, MRS Bull., 2006, 31, 211 28. V. Pardo, A. S. Botana, D. Baldomir, Phys. Rev. B, 2013, 87, 125148 29. D. Li, Y. Gong, Y. Chen, J. Lin, Q. Khan, Y. Zhang, Y. Li, H. Zhang, H. Xie, Nano-Micro Lett., 2020, 12, 36 -

Rights and permissions

This is an open access article under the terms of the Creative Commons Attribution License, which permits use, distribution and reproduction in any medium, provided the original work is properly cited.

Information

Article Metrics

-

Figure 1.

a Optimized carrier concentration of polycrystalline HMS at different temperature calculated based on the single parabolic band model[17]. Copyright 2018, Wiley. b Energy/barrier potential difference and charge transfer among the MnSi, Ag, Graphite, Ge, Si, Pt, SiO2, SiC nano-precipitates and HMS matrix.

-

Figure 2.

Schematic diagram of low-dimensionalization techniques including nanocrystallization, embedding QDs and forming thin film.

Qing Wang is currently a Ph.D. candidate at the College of Physics Science and Technology, Hebei University, China. She received her bachelor's degree and finished the master’s studies at the College of Physics Science and Technology, Hebei University. Her current researches focus on InSb, Bi2Te3, HMS based materials and thermoelectric properties.

Qing Wang is currently a Ph.D. candidate at the College of Physics Science and Technology, Hebei University, China. She received her bachelor's degree and finished the master’s studies at the College of Physics Science and Technology, Hebei University. Her current researches focus on InSb, Bi2Te3, HMS based materials and thermoelectric properties.  Shufang Wang received her Ph.D. from the Institute of Physics, Chinese Academy of Sciences in 2004. Then she joined in the group of professor D. Rémiens at IEMN-CNRS, France as a postdoctoral fellow and after that joined in the group of Professor Xiaoxing Xi at the Penn. State University as a postdoctoral fellow. She is currently a full professor and a group leader at Hebei University. Her researches focus on the fields of photoelectric/thermoelectric materials and devices.

Shufang Wang received her Ph.D. from the Institute of Physics, Chinese Academy of Sciences in 2004. Then she joined in the group of professor D. Rémiens at IEMN-CNRS, France as a postdoctoral fellow and after that joined in the group of Professor Xiaoxing Xi at the Penn. State University as a postdoctoral fellow. She is currently a full professor and a group leader at Hebei University. Her researches focus on the fields of photoelectric/thermoelectric materials and devices.  Zhiliang Li is currently an associate professor in College of Physics Science and Technology, Hebei University, China. He finished his postdoctoral study in School of Materials Science and Engineering, Tsinghua University in 2017. He received his Ph.D. from Department of Materials Science and Engineering, China University of Petroleum, Beijing, in 2015. He specializes in the studies of nano-technology and thermoelectric materials.

Zhiliang Li is currently an associate professor in College of Physics Science and Technology, Hebei University, China. He finished his postdoctoral study in School of Materials Science and Engineering, Tsinghua University in 2017. He received his Ph.D. from Department of Materials Science and Engineering, China University of Petroleum, Beijing, in 2015. He specializes in the studies of nano-technology and thermoelectric materials.

DownLoad:

DownLoad: